Exceptional Wire Drawing Machine China For Your Business

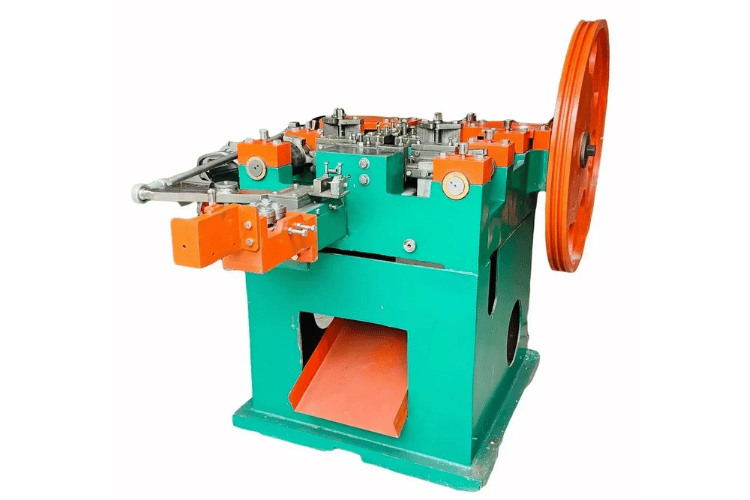

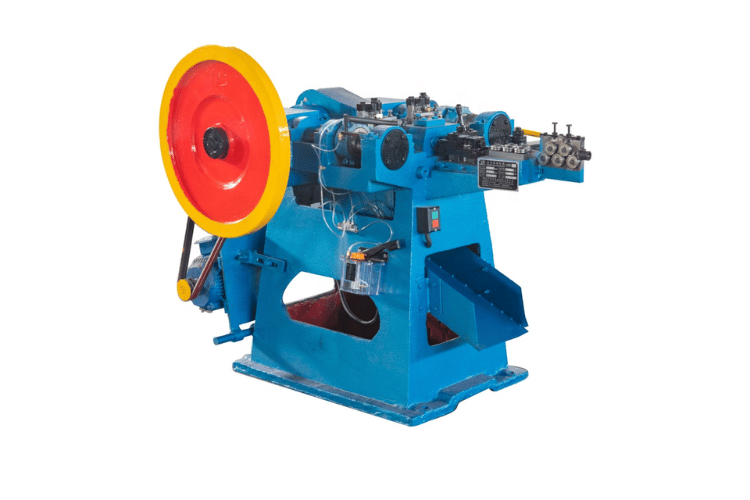

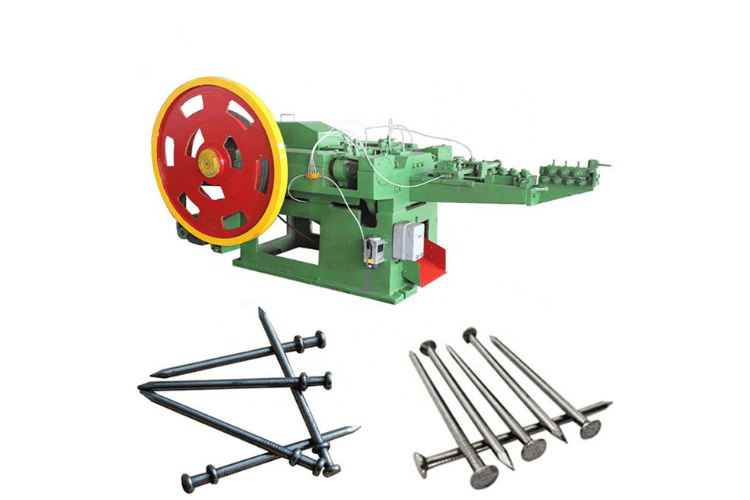

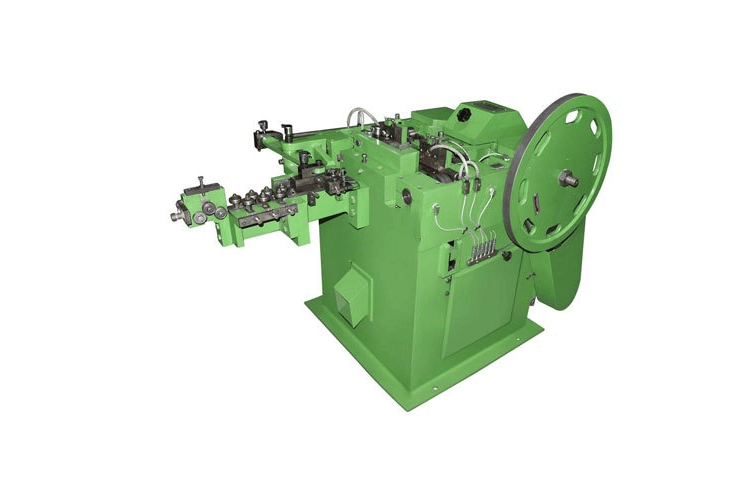

Explore Our Cutting-Edge Nail Making Machine

Awnail: Who We Are

Discover Our Journey

We’ve been at the forefront of making nail machines for 25 years, leading the way with our dedication to top-notch quality, precise engineering, and the latest technology. We’re proud to provide machines that are super efficient, flexible, and can be tailored to your needs, helping your nail production business thrive.

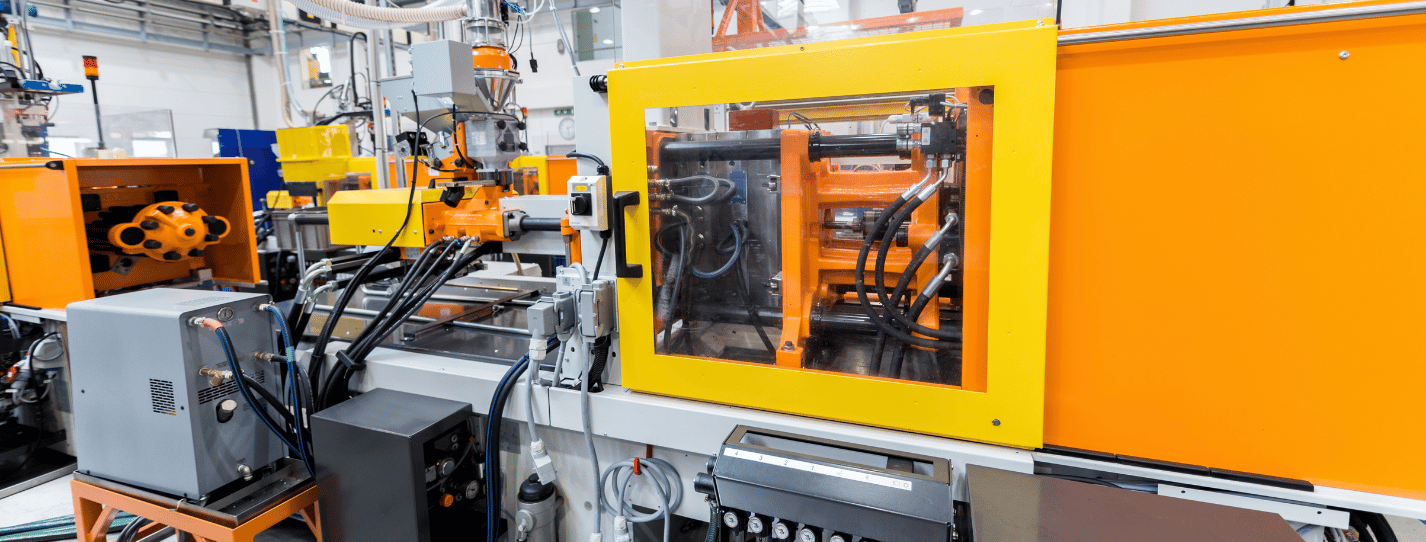

Inside Our Manufacturing Hub

Our huge, modern factory covers 137,890 square feet and is right at the center of where innovation happens. It’s filled with the latest tech and run by expert workers, making sure every nail machine we make is precise and reliable. We do everything from start to finish, which means we keep a close eye on quality and can customize machines just for you.

Our Research & Development Strengths

We’re leading the way in creating new nail machine technology, thanks to our team of experts who always look for ways to do things better. Our focus on research and development means we keep up with the latest trends and offer you the newest solutions. We’re really good at making machines that fit exactly what you need, quickly creating prototypes, and using the latest tech.

Certifications & Accolades

We’re proud of our top-notch certifications, showing our dedication to quality and excellence. Our machines are up to international standards, making sure they’re reliable, safe, and work well. We have ISO 9001 certification, giving you confidence in our commitment to the best quality nail making machines. Choose us for a reliable and certified choice in nail machine manufacturing.

Meet Our Expert Team of Nail Making Machine Innovators

01

Media Team

02

Design Team

03

Engineering Team

04

Sales Team

Our Success Stories

Superior Nail Making Solutions

Quality Control Consistency

Our nail making machines ensure stable product quality with great nail appearance. They hardly ever make mistakes, keeping bad nails to almost none. If something goes wrong or a nail isn’t good enough, the machine will stop by itself. This stops the making of bad nails and keeps the nail quality high and consistent.

High Production Efficiency

Energy Consumption

Accessories of Wire Drawing Machine

Lubricant

Die Polishing

Pointing Machine

Copper

Parts of Wire Drawing Machine

Bench

Capstan

Drum

Pulley

Die

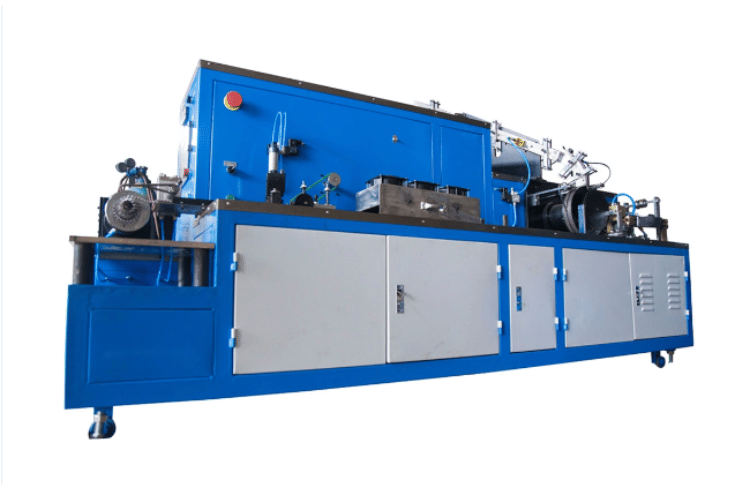

Types of Wire Drawing Machine

Copper Wire Drawing Machine

Gold Wire Drawing Machine

Fine Wire Drawing Machine

Straight Line Wire Drawing Machine

Multi Wire Drawing Machine

Wet Wire Drawing Machine

Fully Automatic Wire Drawing Machine

Intermediate Wire Drawing Machine

Vertical Wire Drawing Machine

Binding Wire Drawing Machine

Single Block Wire Drawing Machine

Electrical Wire Drawing Equipment

Raw Materials of Wire Drawing Machine

Silver

Aluminium

Brass

Stainless Steel

Wire Drawing Machine Price

Steel Wire Drawing Machine Price

Copper Wire Drawing Machine Price

Features and Benefits of Wire Drawing Machine

Features of Wire Drawing Machine

Advanced Control Systems

Durable Die Constructions

Robust Mechanical Design

Benefits of Wire Drawing Machine

Enhanced Production Efficiency

Consistency and Quality of Wire

Versatility in Applications

Applications of Wire Drawing Machine

Electrical Wiring and Cabling

Construction and Infrastructure

Automotive Industry

Consumer Electronics and Appliances

3 Considerations When Buying a Wire Drawing Machine

#1 Material Compatibility

#2 Precision and Control Features

#3 Safety Features and Compliance

Dive Deeper Into Our Resources

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- An In-Depth Guide to Nail Making Machines

Take Action with Our Wire Concrete Coil Steel lron Screw High Speed Roofing Automatic Cement Nail Making Machine

Connect with Us