Are you striving for maximum precision and efficiency in your nail manufacturing processes? The choice between thread rolling and thread cutting can be crucial in achieving these goals.

With years of expertise in the nail machine making industry, I bring a wealth of knowledge about these manufacturing techniques. My insights are grounded in practical experience and continuous observation of industry trends.

Each method has specific applications. Thread rolling involves shaping metal through deformation without material loss, while thread cutting removes portions of the metal to create threads.

In this guide, you’ll discover the complexities of both thread rolling and thread cutting, their advantages, limitations, and the applications they are best suited for.

Read on to know more about these manufacturing techniques.

1. Importance of Threads in Various Industries

Threads are a fundamental component in various industries, serving as the backbone of countless applications. In construction, they are essential for creating strong, reliable connections in structures, where durability and precision are paramount. Similarly, in automotive manufacturing, threads are integral in ensuring the safety and functionality of vehicles, connecting critical components like engine parts and body panels.

In the realm of electronics and machinery, threads play a crucial role as well. They facilitate the assembly of complex devices, allowing for the precise and secure fitting of small parts. This is particularly vital in industries where precision is key, such as in aerospace and medical equipment manufacturing. Here, the accuracy and reliability of threaded connections can mean the difference between success and failure.

2. Understanding Thread Rolling

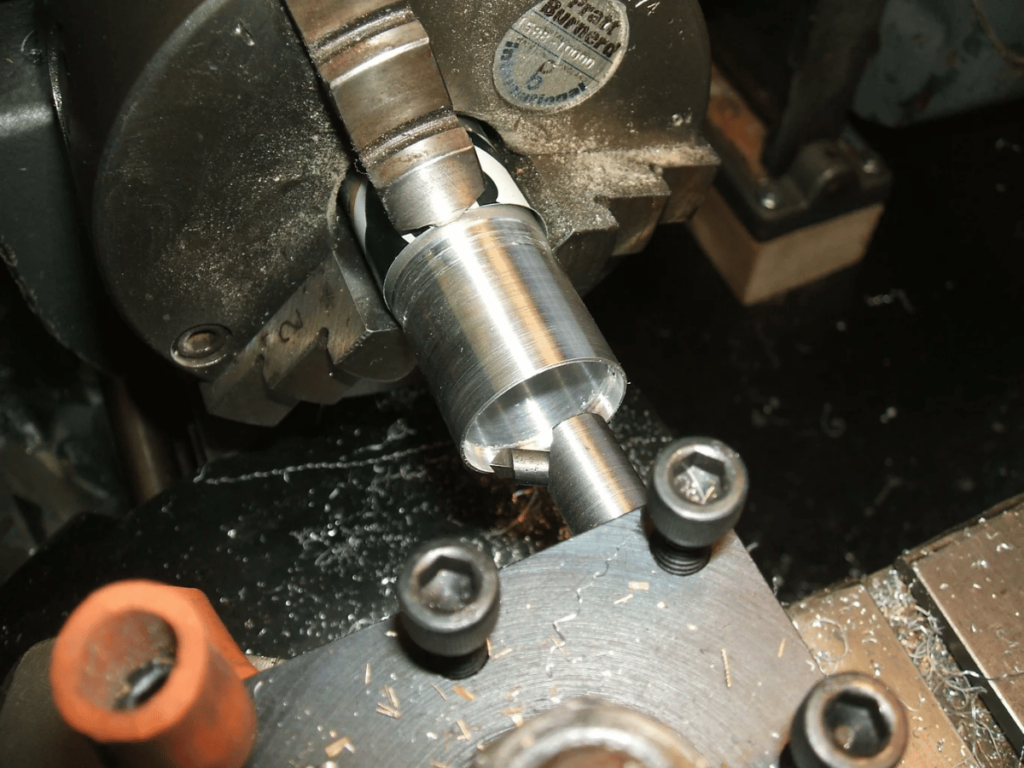

Thread rolling is a process of forming threads by deforming a workpiece. This method involves passing the workpiece between rotating dies, which impress the thread shape into the material. It’s a cold forming process, meaning it does not involve removing material but rather shaping it under high pressure.

Features

- Grain Flow Preservation: Unlike cutting, thread rolling preserves the metal’s grain flow. This process aligns the grain flow with the contours of the threads, enhancing the thread’s strength and resistance to fatigue. This feature is unique to rolling, as cutting disrupts this grain flow.

- No Material Loss: Thread rolling is distinguished by its absence of material loss. The metal is plastically deformed to form the thread, ensuring no metal is shaved off. This contrasts sharply with thread cutting, where material is removed, leading to waste.

- Work-Hardening of Threads: The rolling process naturally work-hardens the metal in the threads. As the metal is compressed and deformed, it becomes harder and stronger. This hardening effect is inherent to thread rolling, a feature not present in thread cutting.

Applications

- Automotive Industry: With the automotive market expected to grow a CAGR of 2.79%, as reported by Industry Research, thread rolling is widely used in this sector for producing durable, high-strength threaded components like bolts, screws, and fasteners. These components are essential for ensuring structural integrity and safety in vehicles in this fast growing industry.

- Construction and Building Materials: In the construction industry, thread rolling is employed to create threaded rods and bars used for concrete reinforcement, and structural connections. The enhanced strength of rolled threads is crucial in these applications, where the integrity of structures is paramount.

- Aerospace Applications: The aerospace industry relies on thread rolling for manufacturing critical fasteners and connectors used in aircraft construction. The process’s capability to maintain material strength and integrity is vital for components that are subjected to extreme pressures and temperatures.

3. Exploring Thread Cutting

Thread cutting involves removing material from a workpiece to form threads. This process uses cutting tools, such as taps and dies, which carve out the thread pattern. It’s a subtractive method, contrasting with thread rolling, and is used for various materials, including those not suitable for rolling.

Features

- Versatility in Material Use: Thread cutting is versatile, applicable to a wide range of materials, including hard and brittle ones. For example, it can be effectively used in the automotive industry for threading critical components made of both softer aluminum and tougher stainless steel.

- Complex Thread Profiles: Thread cutting allows for the creation of complex and custom thread profiles. This capability is essential for specialized applications where unique thread designs are required. It provides flexibility to create threads that are not possible with rolling.

- Adjustable Thread Depth and Diameter: The process offers control over thread depth and diameter. By adjusting the cutting tool, manufacturers can produce threads of varying sizes and depths, providing customization that thread rolling cannot offer.

Applications

- Custom Machinery Manufacturing: Thread cutting is pivotal in custom machinery manufacturing, where unique thread profiles and dimensions are often required. This method allows for precise customization, accommodating specific design needs that are not feasible with standard thread rolling.

- Repair and Maintenance Work: In maintenance and repair sectors, thread cutting is extensively used for restoring or recreating damaged threads on existing machinery and equipment. For instance, its ability to cut threads to match original specifications makes it ideal for repair work, ensuring that components function as intended.

- Instrumentation and Precision Devices: For intricate devices in fields like medical equipment and scientific instrumentation, thread cutting provides the necessary precision. These applications often require finely detailed threads that can only be achieved through the precise removal of material.

4. Key Difference Between Thread Rolling and Thread Cutting

After delving deeper into thread rolling and thread cutting, understanding their differences is essential for making informed decisions in manufacturing processes. Here are the key areas where these two techniques differ:

Process

- Thread Rolling: Thread rolling is a cold forming process where the metal is plastically deformed to create threads. This method involves pressing the workpiece between hardened steel dies that are engraved with the thread profile.

- Thread Cutting: Thread cutting, in contrast, is a subtractive process where material is removed from the workpiece to form threads. This is typically done using cutting tools like taps and dies, which carve out the thread pattern. This method is more about sculpting the thread out of the existing material.

Material Properties

- Thread Rolling: The process of thread rolling strengthens the material due to work hardening. As the metal is compressed, its grain structure aligns with the thread’s shape, resulting in enhanced durability and fatigue resistance. This method is ideal for applications where strength is a critical factor.

- Thread Cutting: In thread cutting, the material’s grain structure is cut through, which can potentially weaken the threads. While it offers versatility in terms of the types of materials that can be used, it does not enhance the material’s inherent strength. This might make the threads less suitable for high-stress applications.

Surface Finish Quality

- Thread Rolling: Thread rolling typically yields a superior surface finish. The rolling process compresses and smoothens the thread surface, leading to a polished and high-quality finish. This not only enhances the aesthetic appeal but also improves the thread’s resistance to corrosion and wear.

- Thread Cutting: Thread cutting can sometimes leave a rougher surface finish. As the cutting tool removes material, it may create microscopic tears or irregularities on the thread surface. But Awnail’s advanced thread cutting machines are designed to minimize these effects, ensuring a smoother finish on the threads.

5. 3 Tips for Choosing the Right Method for Your Needs

Recognizing the distinct differences between thread rolling and thread cutting is vital, but choosing the appropriate method for your specific requirements is a critical step. Here are essential tips to help you decide:

#1 Equipment and Setup Costs

For businesses considering the cost implications, thread rolling generally requires a higher initial investment in specialized equipment. In contrast, thread cutting requires less initial investment and is suitable for operations with limited budgets or those focusing on customized, low-volume production. Awnail offers a range of machines for these methods, making good risk for businesses aiming to optimize their production costs.

#2 Thread Integrity and Strength

Thread rolling enhances thread strength by aligning the material’s grain along the thread, improving its tensile strength. This process, known as cold working, strengthens the thread without removing any material. In contrast, thread cutting cuts through the material’s grain, which can weaken the thread’s overall integrity. Therefore, for applications where thread strength is crucial, thread rolling is often the preferred method.

#3 Material Compatibility

When choosing between thread rolling and thread cutting, consider the material’s ductility. Thread rolling is ideal for ductile materials, as they can endure the deformation process without cracking. On the other hand, thread cutting is better suited for hard or brittle materials, including various alloys and plastics, offering greater versatility across different material types.

| Material Type | Suitable Method | Description |

| Ductile Materials | Thread Rolling | Ideal for materials like aluminum, copper, and mild steel, which can undergo deformation without cracking, resulting in improved thread strength. |

| Hard/Brittle Materials | Thread Cutting | Suited for materials such as hardened steel, titanium, and certain plastics, where cutting through the grain is necessary for threading due to their inherent hardness or brittleness. |

| Versatility | Thread Cutting | Thread cutting offers greater versatility across a wide range of materials, making it suitable for applications where material types may vary. |

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- An In-Depth Guide to Nail Making Machines

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

This comprehensive comparison guide aims to clarify the distinctions and applications of these two essential manufacturing processes. Understanding these differences is key to optimizing your production efficiency and product quality.

For businesses seeking further insights into the best thread forming methods for your specific needs, Awnail is here to assist. For expert guidance tailored to your manufacturing requirements – contact us today.