Are you looking to elevate your nail production with the finest machines on the market? The right choice can significantly impact your operation’s efficiency and output quality.

Leveraging extensive industry experience and a keen eye for technological advancements, I offer a perspective that blends technical know-how with practical insights.

Navigating nail making machines can be a challenging task given the wide range of options available, but certain models stand out for their superior performance, durability, and innovation.

In this guide, we’ll break down the specifications, user experiences, and unique selling points of the industry’s leading nail making machines, providing you with a clear roadmap to making an informed purchase.

Read on to discover the top contenders in the nail making machine industry.

1. Understanding Nail Making Machines

Nail making machines are fundamental tools in the manufacturing sector, designed for efficiency, precision, and durability. These machines vary significantly in terms of size, speed, and output capabilities, catering to diverse production needs. A key aspect to consider is the technological integration, where advancements like automation and computerized controls play a vital role in enhancing production efficiency.

According to market analysis from GitHub, the global nail machine market is expected to grow at a CAGR of 4.6% during the forecast period, underscoring the increasing demand and continuous innovation in this field. Maintenance and operational simplicity are key, affecting longevity and productivity. Choosing the right machine involves balancing these elements for best performance and efficiency.

2. Criteria for Rating Nail Making Machines

Building on the understanding of nail making machines, it’s essential to delve into the criteria that define their quality and performance. Let’s explore the key factors that industry professionals consider when rating these machines:

Durability and Build Quality

Durability is a cornerstone in assessing nail making machines. High-quality machines are constructed with robust materials, ensuring longevity and resilience against wear and tear. A machine’s ability to withstand continuous operation without frequent breakdowns is crucial for uninterrupted production. Build quality directly impacts nail precision, highlighting the need for solid construction to ensure consistent output.

The following table highlights key factors that contribute to the durability of nail-making machines, underlining the importance of build quality for sustained, precise production.

| Factor | Impact on Durability |

| Material Quality | Higher quality materials enhance machine longevity and resistance to wear and tear. |

| Continuous Operation | Machines designed for continuous operation exhibit fewer breakdowns, maintaining consistent production. |

| Build Quality | Solid construction ensures nail precision and durability under rigorous use. |

| Maintenance Ease | Ease of maintenance can significantly extend the operational life of the machine. |

| Technological Features | Advanced features can improve operational efficiency and reduce the strain on critical components, further enhancing durability. |

Speed and Production Capacity

Speed and production capacity are vital for meeting market demands. The best machines offer high-speed production without compromising the quality of nails. This criterion evaluates how effectively a machine can maintain optimal output levels over time, making it a critical factor for businesses aiming to increase productivity and meet large orders efficiently.

Energy Efficiency and Environmental Impact

Energy efficiency in nail making machines is not just about reducing operational costs; it also reflects a commitment to environmental responsibility. Machines that consume less energy and produce minimal waste are increasingly favored. It’s heartening to see brands like Awnail leading the way in this aspect, integrating eco-friendly technologies in their designs.

User-Friendliness and Safety Features

User-friendliness and safety features are paramount in any industrial equipment. Machines should be intuitive to operate, with clear instructions and user interfaces. Safety features like emergency stops, guards, and alarms are essential for protecting operators. This criterion evaluates how well these machines integrate user-centric design and safety measures to ensure a safe and comfortable working environment.

Cost-Effectiveness and Return On Investment (ROI)

Finally, cost-effectiveness and Return On Investment (ROI) are crucial for any business decision. This criterion examines not just the initial purchase price but also the long-term operational costs, including maintenance and energy consumption. The best nail making machines offer a balance between upfront costs and ongoing expenses, ensuring a favorable ROI for businesses.

3. Top Brands and Models in the Market

Exploring the leading brands and models in the nail making machine market provides valuable insights into the industry’s current standards. Here are some of the notable names that have set benchmarks for quality and performance:

Awnail’s Smart High Capacity Nail Making Machine

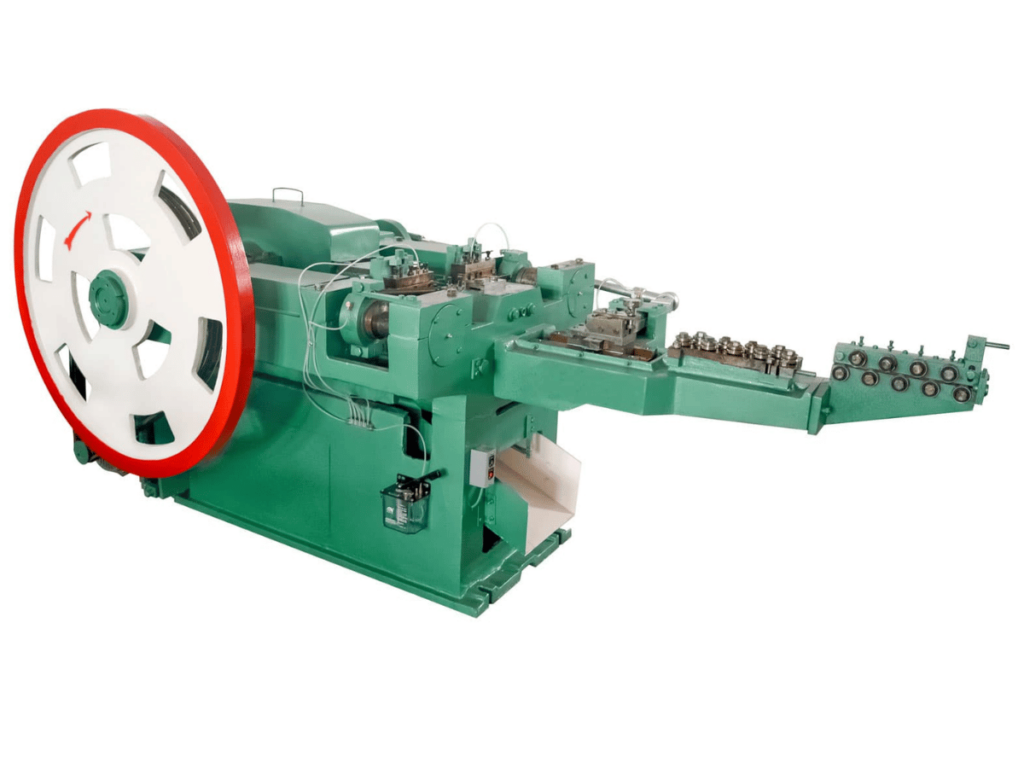

Smart High Capacity Nail Making Machine | Awnail stands out for its versatility and high performance. It’s tailored to handle a diverse range of nail sizes and types, making it an ideal solution for businesses with varied production needs. This model has skillfully integrated flexibility and efficiency solidifying its position as a top contender in the market.

Enkotec MX01

Enkotec is renowned for its high-quality wire nail making machines. Their flagship model, the ENKOnail MX01, is a high-speed rotary wire nail manufacturing machine known for its high capacity, low production costs, and consistent quality nails. This machine represents a significant advancement in nail manufacturing technology, offering a reliable solution for large-scale production.

Conail CN 100

Conail machine excels in its ability to efficiently produce nails with minimal manual intervention. Incorporating a sophisticated feeding system and an advanced nail-making mechanism, the machine adeptly handles wire, cutting it to the desired size. It then shapes these cut pieces into nails, forms the heads of the nails, and applies the necessary finishing touches.

4. Expert Opinions and Ratings

When evaluating nail making machines, expert opinions and ratings provide invaluable insights. Here are some key aspects highlighted by industry professionals:

- Innovation in Technology: Experts rate these machines highly for incorporating cutting-edge technology, with an average rating of 4.5 out of 5. The integration of automation and advanced programming has significantly boosted production efficiency.

- Precision and Accuracy: Precision and accuracy are critical, receiving an expert rating of 4.7 out of 5. The latest models show remarkable consistency in nail dimensions, essential for quality manufacturing.

- Noise and Vibration Levels: The industry standard for noise and vibration control is commendable, with a rating of 4.0 out of 5. Modern machines are designed to operate more quietly, reducing workplace noise pollution.

- User Interface and Control Systems: The user interface and control systems receive a 4.2 out of 5 rating. The focus on user-friendly interfaces and programmable controls has made machine operation more intuitive and efficient.

- Versatility in Nail Types: Versatility in producing various nail types is rated at 4.5 out of 5. These machines are adaptable, capable of handling different sizes and types of nails, meeting diverse market needs.

5. 3 Factors to Consider When Choosing Nail Making Machines

Reflecting on expert opinions and ratings, certain key factors emerge as vital when choosing the right nail making machines. These considerations are essential for ensuring that the selected equipment meets the specific needs of a business. Here are some factors to consider:

#1 Ergonomics and Operator Comfort

Ergonomics and operator comfort are often overlooked but essential. Machines designed with operator comfort in mind can enhance productivity and reduce fatigue. For example, a machine that has adjustable components or user-friendly controls. This aspect is particularly close to my heart, as operator well-being directly impacts overall efficiency.

#2 Machine Compatibility and Adaptability

Another key factor is the machine compatibility and adaptability to different nail types and sizes are paramount. Some machines offer the flexibility to produce various nail types, from roofing nails to finishing nails, without extensive reconfiguration. The ability to adapt to different production requirements without significant downtime is a valuable feature.

#3 Scalability and Future Expansion

Finally, scalability and future expansion possibilities are important. A machine that can easily be upgraded or expanded to meet growing production demands can be a wise investment. For example, choosing a machine that allows for additional modules or increased capacity can be beneficial for businesses planning to scale up their operations in the future.

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

This guide has navigated through the essential aspects of selecting the ideal nail making machine, from understanding key features to evaluating top models and brands. The insights provided here are designed to assist in making informed decisions that align with specific business needs.

For businesses seeking top-notch nail making solutions, Awnail offers a range of high-quality machines suited for various needs. For more details or to discuss your specific needs, don’t hesitate to contact us.