Are you trying to figure out how much a wire drawing machine should cost? It’s not always straightforward, but knowing what influences the price can help you make a smart choice.

As a seasoned expert in the field of industrial machines, I bring valuable insights to help you through the maze of purchasing decisions. My goal is to ensure you find a machine that fits both your budget and your operational needs.

Wire drawing machine prices vary based on technology, capacity, and features, highlighting the need for a buying approach.

In this guide, you’ll discover the details of wire drawing machine costs, including what drives prices and how to evaluate the true value of a machine that supports your business goals.

Read on for smart wire drawing machine investment tips.

1. Understanding the Basics of Wire Drawing Machine Pricing

Navigating through wire drawing machine pricing begins with understanding key factors influencing their cost, especially in a market poised for growth. According to Dataintelo, the global wire drawing machine market is expected to grow at a CAGR of 5.5% from 2022 to 2030. Market growth signals increased demand for advanced, durable machines, directly affecting their pricing.

Moreover, brand reputation and the quality of customer support also play vital roles in determining cost. It’s crucial to factor in operational expenses, including maintenance and energy efficiency, which contribute to the total cost of ownership. A well-informed approach ensures investment balance, aligning cost with quality and performance in a growing market.

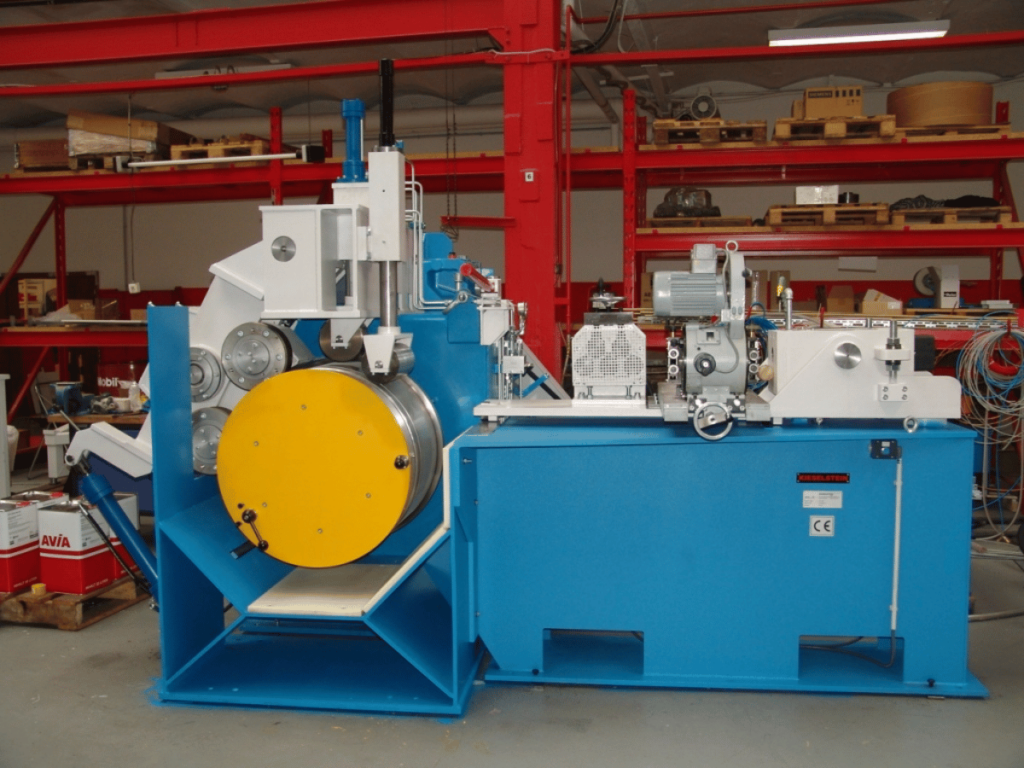

2. Types of Wire Drawing Machines and Their Costs

Building on the understanding of the basics of wire drawing machine pricing, it’s important to delve into the different types of machines and their associated costs. Here’s the common types and their price ranges:

Single-block Wire Drawing Machine

Single-block wire drawing machines are designed for straightforward, efficient wire drawing tasks, their price between $9,000 and $11,000. Ideal for smaller operations or specific applications, they offer simplicity and ease of use. With their compact design, these machines are a cost-effective solution for businesses looking to perform basic wire drawing functions without the need for advanced features.

Multi-block Wire Drawing Machine

Multi-block wire drawing machines are versatile and suitable for a variety of wire types and sizes, their price ranges from $8,000 to $15,000. These machines allow for sequential drawing stages, enhancing both the precision and quality of the final product. Their adaptability makes them a popular choice for businesses requiring flexibility in their production process.

Water Tank Type Wire Drawing Machine

Water tank type wire drawing machines are specialized for drawing fine wires and maintaining consistent wire temperature and lubrication, with a price range of $6,000 to $6,500. This type is particularly effective for materials that require delicate handling, ensuring high-quality output with minimal wire breakage.

Die Fine Wire Drawing Machine

Die fine wire drawing machines are tailored for producing extremely fine wires, also in the price bracket of $6,000 to $6,500. These machines are essential in industries where precision and wire diameter consistency are crucial. Brands like Awnail offer such machines, combining quality construction with advanced technology to meet the specific needs of fine wire production.

3. Key Features that Affect Pricing

When considering wire drawing machines, certain features significantly impact their pricing. Let’s explore the key aspects that play a pivotal role in determining cost:

- Automation Level: The degree of automation directly influences price. Fully automated machines, which minimize manual intervention and boost production efficiency, command higher prices due to their advanced technology and software.

- Speed and Efficiency: Machines designed for higher speeds and efficiency are priced higher. These features reduce production time and increase output, justifying the additional investment.

- Material Quality and Durability: Machines built with high-grade, durable materials tend to be more expensive.This investment in quality ensures longer machine life and reduces maintenance costs.

- Machine Capacity and Size: Larger machines capable of handling high volumes and thicker wires are generally more expensive. Their size and capacity for heavy-duty work require more robust materials and design, leading to higher costs.

- Customization Options: Customizable features, allowing adaptation to specific wire types or sizes, add to the cost. Flexibility in machine operation to accommodate various production needs is a valuable asset, but it increases the machine’s complexity and price.

4. Negotiation Strategies for Better Pricing

After understanding the key features that affect pricing, it’s crucial to consider effective negotiation strategies to achieve better pricing. Let’s delve into techniques that can be leveraged during price negotiations:

Pencil Sharpening

Pencil sharpening involves asking the seller to reduce their price to make the deal more appealing without altering the original offer’s structure. It’s a straightforward strategy used after the initial quote, suggesting the seller can “sharpen” their pencil to improve the proposal. This technique relies on the assumption that vendors have built-in margins that can be adjusted to secure the sale.

Anchoring

Anchoring uses a specific number or price as a starting point in negotiations, heavily influencing the discussion’s direction. By setting an anchor, you establish a reference point for all subsequent negotiations. This could mean starting with a lower bid than you’re willing to pay or presenting a counteroffer significantly different from the initial quote, thereby setting the stage for negotiations towards a more favorable price point.

Whack Back

Whack back is a more aggressive negotiation tactic, where the initial offer or price is met with a significantly lower counteroffer. This shock tactic aims to reset the seller’s expectations and bring them down to a more reasonable negotiation range. It’s particularly effective in markets with high competition or when the buyer believes the initial price is far above the market rate or product’s value.

5. Additional Costs to Consider

Beyond the purchase price, there are additional costs associated with wire drawing machines that should be factored into the overall investment. Understanding these can help in planning and budgeting effectively. Let’s delve into some costs to consider:

Installation and Setup

Installation and setup costs can vary, typically ranging from $100 to $500, depending on the complexity of the machine and the facility requirements. This includes costs for technicians, potential modifications to the workspace, and the initial calibration of the machine. It’s essential to consider these expenses to avoid unexpected budget overruns.

Maintenance and Repairs

Regular maintenance and occasional repairs are crucial for the longevity and efficiency of wire drawing machines. These costs can range from 2% to 3% of the machine’s purchase price annually, depending on usage intensity and machine complexity. For example, replacing worn-out parts in a high-capacity machine might cost several thousand dollars each year.

Training and Operator Costs

Training costs, essential for ensuring safe and efficient machine operation, can range from $2,000 to $2,500, depending on the machine’s complexity and the number of operators being trained. Additionally, the salaries of skilled operators, which can vary widely depending on location and experience, must be accounted for in the operational budget.

6. Financing Options for Wire Drawing Machines

Acquiring a wire drawing machine is a significant investment, and understanding the available financing options can make this process more manageable. Let’s explore some of the specific financing methods that can be utilized:

Bank Loans

Bank loans are a traditional and widely used financing option. They offer the flexibility of long-term payment plans, typically ranging from 1 to 5 years. Interest rates vary based on credit history and the bank’s policy. For example, a business might secure a loan at a 5% annual interest rate to finance a high-capacity wire drawing machine.

Leasing Options

Leasing is an attractive option for businesses not looking to own a machine outright or seeking to avoid a large initial expenditure. Monthly leasing fees are often lower than loan payments, allowing businesses to conserve cash flow while using the equipment. Additionally, some leases offer the option to purchase the machine at the end of the term for a residual amount.

Manufacturer Financing

Many manufacturers, including those of wire drawing machines, offer their own financing solutions. These can be more tailored to the specific product and sometimes offer more competitive rates or terms than traditional bank loans. Manufacturer financing can include deferred payments, lower initial costs, and sometimes even interest-free periods, making it an attractive option for many businesses.

7. 3 Tips on How to Budget for a Wire Drawing Machine

After exploring financing options for wire drawing machines, it’s equally important to focus on effective budgeting strategies for this investment. Here are some specific tips to consider when setting a budget:

#1 Get Quotes

Obtaining multiple quotes from various suppliers is a fundamental step. This allows for a broad understanding of the market rates for wire drawing machines and helps identify the most cost-effective options. Comparing prices and specifications across different brands and models provides a solid foundation for budgeting decisions, ensuring a choice that offers the best value for money.

#2 Consult to Expert

Seeking advice from industry experts can significantly aid in making an informed decision. Experts, with their extensive knowledge of the market and technology, can provide insights into which machine models offer the best performance for their price. Brands like Awnail, known for their expertise in wire drawing technology, can provide clarity and direction in selecting a machine that meets specific business requirements.

#3 Consider Future Scalability

When budgeting for a wire drawing machine, it’s important to consider the equipment’s scalability. Machines are designed to grow with your business, providing options to upgrade or expand capabilities without the need for a complete replacement. Investing in scalable solutions can be more cost-effective in the long run, ensuring that the machine continues to meet production demands as your business expands.

The table below outlines key factors to consider when assessing the future scalability of a wire drawing machine, ensuring it aligns with your business growth strategy.

| Factor | Description |

| Upgradeability | Ability to integrate advanced features or technologies without replacing the entire machine. |

| Capacity Expansion | Options to increase production capacity to meet growing demand. |

| Compatibility | The machine’s ability to work with new materials or wire types as your product range expands. |

| Maintenance and Support | Availability of ongoing support and maintenance to extend the machine’s lifespan and efficiency. |

| Cost Efficiency | Long-term savings achieved by avoiding the need for complete replacement as your business scales up. |

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- An In-Depth Guide to Nail Making Machines

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

This comprehensive guide serves as a valuable resource in navigating the complexities of purchasing a wire drawing machine, offering insights from pricing strategies to budgeting tips. It equips businesses with the necessary knowledge to make informed decisions for their specific needs.

Considering the range of options and factors discussed, Awnail stands out as a reliable choice for quality wire drawing machines. For further information, feel free to contact us today. We’re here to assist you!