PRODUCT FEATURES

Wet Wire Drawing Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud to Offer a Wide Variety of Nail Making Machines

If you are looking for something specific that isn’t listed on our website yet, just contact us today.

ABOUT US

Who is awnail.com

awnail.com have seen that today there are also many nail making machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and awnail.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

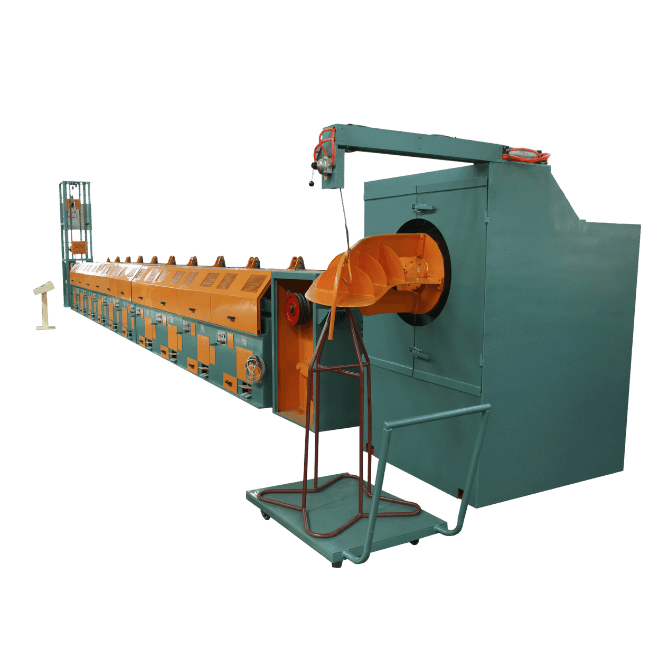

Wet Wire Drawing Machine

Wet Wire Drawing Machine is a precision instrument that is used to produce high-quality wire.

It employs a wetting system that lubricates the wire as it is drawn through a die, which minimizes wear and produces a smooth finish.

Wet Wire Drawing Machine is available in both manual and automatic versions, so you can choose the one that best meets your needs.

It is also made of durable materials that can withstand heavy use, so you can rely on them for years to come.

Table of contents

1. Wet Wire Drawing Machine Definition and How It Works

Wet wire drawing is a term used for automated wire drawing. Wet wire drawing process is less common than dry wire drawing machines because it is more complex, although it can be an effective option for high-volume applications or cases with difficult geometry.

Wet diagrams make use of manual feeding of individual wires to create intricate shapes, which would be impossible using dry loop-die systems. Wet draw processes typically occur at low speeds (<20m/min), often requiring different tooling, and can produce long thin shafts or novel shapes that are not feasible with dry die technologies.

Wet drawing is often used for forming very small or thin wires, however, it can also be adapted to larger part sizes. Wet wire drawing machines are typically more complex than dry loop-die systems due to the need for additional tooling and clamping mechanisms.

Wire Drawing Machine design is varied. Wet wire drawing machines are available in manual feed, semi-automatic & fully automatic models. Wet Wire Drawing Machine is a device that is used to reduce the thickness of metal wires by pulling them through a series of progressively smaller dies.

Wet Wire Drawing Machine usually consists of three parts: the driving unit, the wire guide, and the drawing die. The driving unit uses a motor to turn a set of gears, which in turn rotate the wire guide and the drawing die.

Straight Line Wire Drawing Machines typically use a manually fed wire that is fed into the machine at one end and drawn out through the drawing die at the other. Wet Wire Drawing Machine is commonly used to produce metal wires with different shapes.

As the wire draw machine moves through the dies, it is reduced in size. Wet wire drawing machine parts are used to reduce the diameter of a metal wire by pulling it through a series of progressively smaller dies.

2. Wet Wire Drawing Machine Key Features

The Wet Wire Drawing Machine is a machine that reduces the size of the wire using a die. It uses a wet process and can be done in an enclosed space to reduce sparks and other possible fire hazards.

The Wet Wire Drawing Machine has many key features, such as:

Wet Wire Is Easy To Clean

One of the Wet Wire Drawing Machine’s key features is that it is easy to clean. This is important because it helps to reduce the chances of bacteria or other contaminants affecting the quality of the wire.

Wet Wire Has One Die for Multiple Wire Sizes

Another Wet Wire Drawing Machine key feature is that it uses a single die to create different-sized wires. For example, if the Wet Wire Drawing Machine were to use a different sized die, a user would have to purchase multiple dies instead of just one.

This Wet Wire Drawing Machine key feature allows for one machine to meet multiple wire-size needs.

Wet Wire Drawing Machine Is Energy Efficient

Another Wet Wire Drawing Machine key feature is that it is energy efficient. It uses less electricity than some other drawing machines, which helps to reduce the overall power consumption of the device.

This Wet Wire Drawing Machine key feature makes it easier for the machine to be compliant with different environmental standards.

Wet Wire Drawing Machine Is Easy To Use

Another Wet Wire Drawing Machine key feature is that it is easy to use. It does not require any special training, which means that the Wet Wire Drawing Machine can be used by multiple people without having to train them on how it works.

Wet Wire Drawing Machine Is Compact

The Wet Wire Drawing Machine’s final key feature is that it is compact. It takes up less space than other wire drawing machines, which makes the Wet Wire Drawing Machine useful for smaller factories or places where space is limited.

This Wet Wire Drawing Machine key feature allows for the machine to be used in places it otherwise could not, which makes the Wet Wire Drawing Machine accessible to many users.

Wet Wire Drawing Machine Is Well-Built

While the Wet Wire Drawing Machine has multiple key features, one of its best qualities is that it is built to be used for a long time. Many Wet Wire Drawing Machines are made using materials that can last for decades, so the Wet Wire Drawing Machine is a good investment.

Wet Wire Drawing Machine Has Quick Change Die

Another Wet Wire Drawing Machine key feature is that it has a quick change die. The Wet Wire Drawing Machine’s die can be changed in seconds instead of taking up to an hour like on some other machines, which makes the Wet Wire Drawing Machine more efficient than other wire drawing machines.

Wet Wire Drawing Machine Is Driven by Independent Motor

The Wet Wire Drawing Machine has a powerful independent drive, making it easy to use and improving the Wet Wire Drawing Machine’s functionality. The Wet Wire Drawing Machine’s independent drive also creates a better die change speed, which makes it efficient and easy to use.

Wet Wire Drawing Machine Is Well-Made

Wet Wire Drawing Machine is well made. Wet Wire Drawing Machine has a solid base that helps to make the Wet Wire Drawing machine stable and increases its durability. Wet Wire Drawing Machines are useful machines because they can be used for decades without breaking down.

Therefore, the Wet Wire Drawing Machine has many key features that make it a useful and efficient machine in various applications. Medium and high carbon steel wire drawing machine is suitable for cutting high-strength steel wire.

3. Parts & Construction of Wet Wire Drawing Machine

The Wet Wire Drawing Machine is a drawing machine that uses wire as the raw material. The Wet Wire Drawing Machine has some important parts which are used to draw or pull the wire.

Some of these parts are given below:

The Wire Rollers

The Wire Rollers are the first part of the Wet Drawing Machine that the wire comes into contact with. The Wire Rollers help to straighten and align the wire as it enters the machine.

The Drawing Die

The Drawing Die is the second part of the Wet Drawing Machine that the wire comes into contact with. The Drawing Die is responsible for pulling the wire through the machine.

The Driving Pulley

The Driving Pulley is the third part of the Wet Wire Drawing Machine that the wire enters. In Wet Wire Drawing Machines, this will be a grooved pulley because mechanical power from an external source is needed to drive it.

The Guide Rollers

The Guide Rollers are what guide the wire into the Drawing Die. They are located on either side of the Driving Pulley.

The Wire Stoppers

The Wire Stoppers are also known as the Stopper Rollers because they stop the wire through Wet Wire Drawing Machines by applying lateral pressure against it. This prevents the wire from moving forward as it is being drawn.

The Wire Guide Cones

The Wire Guide Cones are part of the Wet Drawing Machine that guides the wire into the Drawing Die. They are located on either side of the Driving Pulley. Wet Wire Drawing Machines use these to ensure that the wire does not leave the Wet Wire Drawing Machine during operation.

With the above parts, the machine is able to draw wires with different diameters. Wet wire guide rings help in smooth movement of Wet wire while Wet Wire Drawing Machine Tension Roller applies the required tension on Wet wire.

4. Step by Step Guide to Use Wet Wire Drawing Machine

The Wet Wire Drawing Machine is a machine that draws wire. The Wet Wire Drawing Machine can be used for wire drawing, and to reduce the diameter of a rod’s ends.

Here is a step by step guide to using Wet Wire Drawing Machine:

Step#1 Assemble Wet Wire Drawing Machine

The Wet Wire Drawing Machine is a simplified version of the more complex machines used to draw wires. A Machine has many of the same components as other kinds of drawing machines, but it lacks some components that are not necessary for drawing wires.

The Machines come with three rollers, an axle, three clamps to hold the Wet Wire Drawing Machine together (two small ones and one large one), a guide arm for holding the Wet Wire Drawing Machine’s wire guides in place, and two-wire guides.

Step#2 Load Wet Wire Drawing Machine

Wet Wire Drawing Machines are loaded with a gas burner and steel wire. The wet Wire Drawing Machine’s come with two wire guides for holding the wire as it is drawn through the Wet Drawing Machine.

There are some Wet Wire Drawing Machines that do not include gas burners. These machines require a separate gas burner to heat the wire before it goes into the Wet Wire Drawing Machine, and to heat the Wet Wire Drawing Machine’s guides.

Step#3 Heat Wet Wire Drawing Machine

A Wet Wire Drawing Machine has three locations that require heat for the wire drawing process. Threading the Wet Wire Drawing Machine with a gas burner will generate enough heat to draw the wire, but additional heating will speed up the process.

The Wet Wire Drawing Machine’s guides are heated to keep them from cooling before the wire has drawn through it all of the ways. These components are heated in a separate gas burner.

Step#4 Insert Wet Wire

The Wet Wire Drawing Machine is ready to draw wire. Wet Wire Drawing Machines use a gas burner to heat the wire before it is inserted into Wet Wire Drawing Machine.

Step#5 Draw Wet Wire

To draw Wet Wire through Wet Wire Drawing Machine, clamp Wet Wire Drawing Machine’s wire guides against the guide arm. Load steel wire on the right-hand side of Wet Wire Drawing Machine, leaving slack in Wet Wire for easy feeding.

Rotate Wet wire to make sure it will be fed correctly when clamped on the guide arm. Clamp left-hand wire guide in position and rotate rod clockwise with a lot of pressure so that wire does not slide back down.

Step#6 Allow Wet Wire To Cool

Wet Wire Drawing Machines allow the heated wire to cool before removing it. Wet Wire Drawing Machines are also allowed to cool for additional safety reasons. Wet Wire Drawing Machines should not be touched by bare skin while they are still warm because the heat will burn the flesh.

Wet Wire Drawing Machines should always be handled with gloves or pliersbecause of their heated state. Machines that draw wire with a large wire diameter have a cooling period before it is removed.

Wet Wire Drawing Machines that draw wire with small diameters cool quickly and are immediately removed from Wet Drawing Machine to avoid overheating wire.

Step#7 Remove Wet Wire From Wet Wire Drawing Machine

Machines remove the wire by rotating three rollers around an axle. Machines use a wire guide to hold the wire steady as it is removed. Wet Wire Drawing Machines for drawing thick wire also includes a copper or rubber roller that presses down on the machine’s clamps and releases them once the machine has been turned a few degrees.

Wet Wire Drawing Machines for drawing thin wire do not require a release mechanism because it releases wire once the Wet Wire Drawing Machine’s clamps have been turned a couple of degrees.

Step#8 Cut Wet Wire

The wet Wire Drawing machines comes with a wire cutter that is located on the machine’s frame. The wire cutter is used to make a clean cut on the Wet Wire Drawing Machine’s drawn wire.

Wet Wire Drawing Machines that draw wire with large diameter has a wire cutter that is larger and easier to use than Wet Wire Drawing Machines that draw wire with a small diameter. Wet Wire Drawing Machines that draw wire with a small diameter have a wire cutter that is smaller to accommodate the size of Wet Wire Drawing Machine.

Step#9 Clean Wet Wire

Clean Wet Wire by wiping it with a clean cloth. Wet Wire Drawing Machines for drawing thin wire is immediately removed from the machine to avoid overheating wire. Machines allow the heated wire to cool before removing it.

Wet Wire Drawing Machines are also allowed to cool for additional safety reasons. Machines should not be touched by bare skin while they are still warm because the heat will burn the flesh.

Step#10 Measure Wet Wire

After the machine has been cleaned, it is ready to measure Wet Wire. Machines use a vernier scale to measure Wet Wire. Wet Wire Drawing Machine for drawing thick wire has a range of 0-6 inches.

Wet Wire Drawing Machine for drawing thin wire has a range of 0-1/4 inches. Wet Wire Drawing Machine for drawing thick wire has a maximum Wet Wire Drawing Machine of 7 inches. Wet Wire Drawing Machine for drawing thin wire has a maximum Wet Wire Drawing Machine of 1/2 inch.

Step#11 Store Wet Wire

Machines for drawing thick wire store Wet Wire Drawing Machine in a safe place. Machines for drawing thin wire can be stored in a toolbox or a plastic bag. Machines are also stored in boxes, crates, or cabinets. The machine can be purchased along with Wet Wire Drawing Machine equipment to complete Wet Wire Drawing Machine kits.

As you can see, Wet Wire Drawing Machine isn’t as difficult to use as you may have originally thought. Wet Wire Drawing Machine has many uses and is a great investment for those who need to draw wires with different diameters.

Here’s a video of the Wet Wire Drawing Machine in action!

5. Benefits of Using Wet Wire Drawing Machine

There are many benefits of the Wet Wire Drawing Machine.

Some of them are as follows:

| No. | Benefits |

|---|---|

| 1 | Wet Wire Drawing Machines Are Cost-Effective |

| 2 | Wet Wire Drawing Machines Are Time-Saving |

| 3 | Wet Wire Drawing Machines Are Durable |

| 4 | Wet Wire Drawing Machines Are Safe |

| 5 | Wet Wire Drawing Machine Can Be Used by Anyone |

Wet Wire Drawing Machines Are Cost-Effective

The Wet Wire Drawing Machine is a machine that is used for drawing metals into wire. This machine can be used in manufacturing, or you can use it by yourself to make your metal creation.

The Wet Wire Drawing Machine costs less than other draw-wire machines. It will be able to help you manufacture your idea without spending too much money.

Wet Wire Drawing Machines Are Time-Saving

If you use Wet Wire Drawing Machine, this machine is very fast at drawing metals into wire. The Wet Wire Drawing Machine can help you quickly draw the metal into a wire that is constantly being drawn, so you do not have to wait a long time.

Wet Wire Drawing Machines Are Durable

The Wet Wire Drawing Machine can be used for a long time because it is made from quality steel and features a sturdy construction so that this machine does not easily break or wear down due to normal use.

Wet Wire Drawing Machines Are Safe

The Wet Wire Drawing Machine is completely safe because Wet Wire Drawing Machine features safety devices are built in Wet Wire Drawing Machines to give you peace of mind when using Wet Wire Drawing Machine.

Wet Wire Drawing Machine Can Be Used by Anyone

Anyone who uses Wet Wire Drawing Machine will feel comfortable with the Wet Wire Drawing Machine quickly and easily without stress, so you do not need to worry about Wet Wire Drawing Machine will get you.

In conclusion, Wet Wire Drawing Machine is a machine that has many benefits for people who use the Wet Wire Drawing Machine. You can see from the description above Wet Wire Drawing Machines have a lot of benefits, so do not waste your time and immediately look at Wet Wire Drawing Machines to get your product quickly and easily!

6. Where to Find Wholesale Wet Wire Drawing Machine Manufacturers

If you’re in the market for a Wet Wire Drawing Machine, it’s important to do your research and find a reputable manufacturer.

Here are a few places to start:

A quick search online will turn up dozens of Wet Wire Drawing Machine manufacturers. Be sure to read reviews and compare prices before making a purchase.

Alibaba

Alibaba is a great resource for finding wholesale suppliers of all types of products, including Wet Wire Drawing Machines. Just be sure to vet any potential suppliers before placing an order.

Local Trade Shows

Often, local trade shows will feature Wet Wire Drawing Machine manufacturers and distributors. This is a great opportunity to compare products and prices from different suppliers face-to-face.

Wet Wire Drawing Machine Blogs

Wet Wire Drawing Machine suppliers often have their blogs. This is a great place to get to know Wet Wire Drawing Machine manufacturers and learn more about what they have to offer.

Wet Wire Drawing Machine Forums

Wet Wire Drawing Machines are used in all kinds of different industries, and Wet Wire Drawing Machine forums are a great place to learn more about how Wet Wire Drawing Machines are used.

Awnail

If you’re looking for a reliable wet wire drawing machine manufacturer, Awnail is one of the leading suppliers in the industry. Our Wet Wire Drawing Machines are designed to increase productivity and reduce costs in factories where wire drawing is a critical process.

With decades of experience in Wet Wire Drawing Machine design, manufacturing, and service, Awnail has everything you need to ensure a smooth production line every time. For more information contact us at Awnail.

7. Qualities of a Reliable Wet Wire Drawing Machine Manufacturer

When looking for a reliable wet wire drawing machine manufacturer, it is important to consider certain qualities that will ensure you receive a quality product.

Here are the qualities to look for when considering a Wet Wire Drawing Machine Manufacturer:

Experience

A Wet Wire Drawing Machine Manufacturer that has years of experience in the industry will be able to provide a higher quality product than someone who has recently started.

An experienced Wet Wire Drawing Machine Manufacturer will know important tips and tricks, be aware of the newest technologies, and have completed similar projects previously.

Attention to Detail

The Wet Wire Drawing Machine Manufacturer you choose should be paying attention to all of the important details, from small screws and nuts to mega components. Attention to detail is a mark of a Wet Wire Drawing Machine manufacturer that will offer a superior product.

Customer Service

The Wet Wire Drawing Machine Manufacturer should aim to fully meet your needs and provide an optimal customer experience. They should be available to answer questions, offer insight, and provide assistance before, during, and after the Wet Wire Drawing Machine’s production.

Willingness To Go Above and Beyond

A Wet Wire Drawing Machine Manufacturer that is willing to go above and beyond to ensure you are satisfied is an important quality in a Wet Wire Drawing Machine manufacturer.

A Wet Wire Drawing Machine Manufacturer that can’t be reached after a job is complete will not be beneficial, so choose one that has no problem staying in touch or contacting you before and after.

Unwavering Ethics

A Wet Wire Drawing Machine Manufacturer that has unwavering ethics when it comes to business operations and relationships with clients is important. They should have strict guidelines, values to uphold, and be transparent with their Wet Wire Drawing Machine customers.

Reasonable Pricing

A Wet Wire Drawing Machine Manufacturer with reasonable pricing for their Wet Wire Drawing Machines allows more clients to receive Wet Wire Drawing Machines. The Wet Wire Drawing Machine manufacturer should be within a price range with the Wet Wire Drawing Machine’s value and quality as factors.

After Sale Service

A Wet Wire Drawing Machine Manufacturer that is willing to offer after sale services allows their Wet Wire Drawing Machine customers to be able to repair and improve Wet Wire Drawing Machines.

After sale services can be a great way to improve Wet Wire Drawing Machines and ensure they are always running smoothly.

It’s important to consider certain qualities when looking for a Wet Wire Drawing Machine Manufacturer.

8. Average Cost of Wet Wire Drawing Machine

Wet wire drawing machines are an essential part of the wire manufacturing process, and as such, come at a cost. The average cost of a wet wire drawing machine can vary depending on the size and make of the machine, but typically ranges from $10,000 to $100,000.

This price tag can be prohibitive for some smaller businesses, but there are several factors to consider when deciding whether or not to purchase a wet wire drawing machine.

The most important consideration is the volume of wire that will be produced. If the business is expecting to produce a high volume of wire, then the investment in a wet wire drawing machine is likely to be worth it. However, if the volume of wire produced is relatively low, then the upfront costs of purchasing a machine may be too high.

Wet wire drawing machines come in a range of sizes, from small machines that can produce up to 500 feet per minute with a 4-inch diameter to large units that can produce several thousand feet per minute and diameters as great as 36 inches.

Therefore, the size of the machine that needs to be purchased depends on how much wire is being produced each month, and the average cost of a wet wire drawing machine should vary accordingly.

9. 5 Tips Before Buying Wet Wire Drawing Machine

When buying a wet wire drawing machine, there are a few things you should keep in mind. Machines vary significantly in price and quality, so it’s important to do your research before making a purchase.

Here are a few tips to help you choose the right machine for your needs:

#1 Research Wet Wire Drawing Machine Brands

Since there are many brands of wire drawing machines available for purchase, it’s important to do some research about different brands. Look at reviews and detailed descriptions about the brand and model that you’re considering.

#2 Find Wet Wire Drawing Machine for the Right Application

After carefully choosing a brand, you should consider what type of machine will work best for your specific application. For example, if you need to draw metal into fine wire, then you’ll want to purchase a machine that specializes in drawing smaller gauges of wire.

Also, consider other factors like how long you want the wire to be and how quickly you need your product.

#3 Get Wet Wire Drawing Machine from a Reliable Source

One of the most important tips for buying a wet wire drawing machine is to purchase it from a dependable source. If you purchase your machine from the manufacturer, then you’ll have access to the technicians who designed the machine. This will give you easier access to technical help if any problems arise.

#4 Compare Wet Wire Drawing Machine Costs

It’s important to compare the cost of different models before making a purchase. However, it’s also important to consider other factors like speed and wire gauge size when comparing wet wire drawing machine prices.

Although a more expensive machine may cost more up front, the additional features and capabilities may be worth it for your specific application.

#5 Consider Wet Wire Drawing Machine Maintenance Costs

Wet wire drawing machines require regular maintenance to ensure that they continue running at peak performance. It’s important to factor the price of maintenance into your operating budget when purchasing a machine.

Even if you get lucky and buy a less expensive wire drawing machine, it will still need upkeep over time so keep this in mind when making a purchase.

In conclusion, these are a few tips you should consider before buying a Wet Wire Drawing Machine. You will need to make sure that you have selected the right machine for your needs and purchased it from a dependable source.

This will help you continue to save money in the long term. Be sure to get a Wet Wire Drawing Machine that will work for your particular application and get it from a reliable source.

10. Conclusion

Our Wet Wire Drawing Machine is the latest and most advanced machine on the market today. It offers several benefits that other machines do not, including the ability to draw wire at high speeds and with low noise levels.

Our machine is perfect for any business that wants to increase efficiency and decrease costs. With our machine, you will be able to draw wire quickly and easily, without sacrificing quality or performance.

Contact us at Awnail to learn more about our Wet Wire Drawing Machine!