PRODUCT FEATURES

Hydraulic Thread Rolling Machine Manufacturer To Rocket Your Business

PRODUCTS

Proud to Offer a Wide Variety of Nail Making Machines

If you are looking for something specific that isn’t listed on our website yet, just contact us today.

ABOUT US

Who is awnail.com

awnail.com have seen that today there are also many nail making machine companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and awnail.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

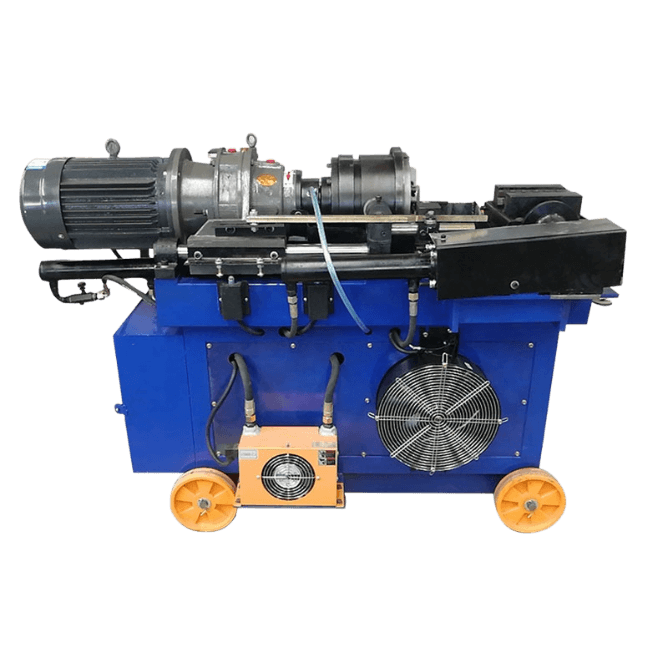

Hydraulic Thread Rolling Machine

The Hydraulic Thread Rolling Machine is a machine used to roll metal wire into coils. It is designed to be easy to operate and maintain, increasing efficiency for the user.

This machine can be used for a variety of applications, including rolling steel wires and cables into coils.

The machine has an automatic lubrication system that provides constant oiling of the parts that are most susceptible to wear during operation. By using this system, it reduces maintenance costs associated with keeping the equipment maintained.

Table of contents

1. Hydraulic Thread Rolling Machine Definition and What Does It Do

A Hydraulic Thread Rolling Machine is a device used to create screws, nails, or other fasteners from the wire. It uses hydraulic pressure to deform the wire into a screw or nail shape. Hydraulic Thread Rolling Machines can also be used to roll the ends of screws and nails, allowing them to tighten and fasten even better.

Hydraulic Thread Rolling Machines are now commonly used in manufacturing factories throughout the world. They’re very versatile, as they can be used to create virtually any type or size of screw or nail that’s needed.

The Hydraulic Thread Rolling Machine was created to help save time in factories that create screws or bolts. They can also be used to flatten wire into a strip for further manufacturing processes.

Hydraulic Thread Rolling Machines reduce the cost of creating new screws or bolts, as they’re more efficient than other types of machinery. A semi-automatic hydraulic threading machine is also less expensive to use on a day-to-day basis.

Hydraulic Thread Rolling Machines are commonly used in factories that create screws or nails for the construction industry. This is due to their prevalence throughout the construction industry.

Here’s a video of how hydraulic thread rolling machines work!

2. Hydraulic Thread Rolling Machine Key Features

Hydraulic thread rolling machines have many features that make them versatile and powerful tools. Hydraulic thread rolling machines are important tools in any workshop. Some of these features include:

Versatility

Ability to roll threads on a variety of materials, including wire nails and screws. These machines are used to form screws, nails, and other metal objects.

Hydraulic thread rolling machines work by using a hydraulic cylinder to push the object into a die.

This gives the object a smooth and consistent thread. Hydraulic machines are great for fast threading and can be used on a wide range of metals.

Speedy

Hydraulic power provides the force needed to roll threads quickly and easily.

Precision

Precise adjustment lets you control the depth and size of the threads.

Durability

Durable construction for years of reliable use is an important aspect of the thread rolling machine.

3. Types of Hydraulic Thread Rolling Machine

Hydraulic thread rolling machines are machines that are used to create screws and nails. They come in a variety of different types, including the following:

Single Die Hydraulic Thread Rolling Machines

These machines are used to create screws. They have one die that is used to create the screw’s threads.

Multi-Die Hydraulic Thread Rolling Machines

These machines are used to create nails. They have multiple dies that are used to create the nail’s threads.

Hydraulic Thread Rolling Machine (Pipe)

These machines are used to create screws and nails in a hydraulic press. They can also be referred to as Hydraulic Pipe Roll Forming Machines or Hydraulic Press Roll Forming Machines.

Hydraulic Wire Nail Rolling Machine

This machine is used to roll from the wire into nails. Hydraulic Wire Nail Rolling Machines are also used to create nails. They have multiple dies that are used to create the nail’s threads.

Hydraulic Groove Rolling Machine

Hydraulic Groove Rolling Machines are used to roll form grooves in screws and bolts. It looks similar to other forms of Hydraulic Thread Rolling Machines.

Hydraulic Groove Rolling Machines are also referred to as Hydraulic Machine Roll Forming Machines.

Hydraulic Weldless Fittings

Hydraulic Weldless Fittings can be used to create bolts and screws. Hydraulic Weldless Fittings are often made specifically for Hydraulic Pipe Thread Rolling Machines.

4. Different Types of Hydraulic Thread Rolling Machines and Their Average Prices!

| Types | Average Price |

|---|---|

| Single Die Hydraulic Thread Rolling Machine | $2,500 |

| Multi-Die Hydraulic Thread Rolling Machine | $3,000 |

| Hydraulic Thread Rolling Machine (Pipe) | $4,000 |

| Hydraulic Wire Nail Rolling Machine | $5,000 |

| Hydraulic Groove Rolling Machine | $6,000 |

| Hydraulic Weldless Fittings | $7,000 |

5. Advantages of Using Hydraulic Thread Rolling Machine

Hydraulic thread rolling machines are a type of machine that is used to create screws, nails, and other fasteners. There are several advantages to using a hydraulic thread rolling machine:

Precision and Accuracy

Hydraulic thread rolling machines are very precise, and they can create very accurate screws and nails. This means that the products you create with a hydraulic thread rolling machine will be of the highest quality.

Durability

Hydraulic thread rolling machines are extremely durable. They can withstand a great deal of wear and tear, which means they will last for a long time.

Easy to Operate

Hydraulic thread rolling machines are easy to use. They are simple to operate, and even those who have little experience with machines can use them effectively. Hydraulic thread rolling machines can also be used by several people at once.

Economical

Hydraulic thread rolling machines are economical, as they allow you to save money on materials and labor. Hydraulic thread rolling machines will help you make the most out of the resources that you have available.

Safe

Hydraulic thread rolling machines are very safe. Hydraulic thread rolling machines feature advanced safety features, so accidental injuries are unlikely.

Hydraulic thread rolling machines will allow you to create products without the risk of injuring your workers or yourself.

Reduces Turnaround Time

Hydraulic thread rolling machines can produce threads quickly and easily, so turnaround time is reduced. Your employees will be able to create screws and nails quickly, which will help you meet the needs of your business and allow you to grow.

Hydraulic thread rolling machines can also reduce labor costs and boost productivity.

Flexible

Hydraulic thread rolling machines are flexible, so they can create whatever kind of screw or nail that you need for any given application.

Hydraulic thread rolling machines will allow you to meet the needs of your customers, so they are certain to return. Hydraulic thread rolling machines can also help create custom screws for specific uses.

6. Lifespan of Hydraulic Thread Rolling Machine

The lifespan of a Hydraulic Thread Rolling Machine is about 10 years. After that time, the machine will need to be replaced to continue producing quality screws and nails.

Hydraulic machines are more durable than other machines because they are placed in an enclosed area. This machine is also one of the hydraulic tools which need regular maintenance, especially clean up after each job.

Hydraulic Nailers and other Hydraulically Operated Tools which receive regular maintenance will last longer.

7. Hydraulic Thread Rolling Machine Price

The Hydraulic Thread Rolling Machine Price is US$10,000. You could also get Hydraulic Thread Rolling Machine Price in US$10000-US$50000.

The price is determined by the manufacturer and the automation grade of the model name number.

The roll thread machine price can range from US$10000 to up to thousands of dollars depending on the machine’s quality.

8. Where to Find the Best Deals on Hydraulic Thread Rolling Machine

Hydraulic thread rolling machines with a thread rolling machine price are a type of machinery that is used to form metal screws, bolts, and rods.

They are available in a variety of sizes and can be used for a variety of purposes. If you’re in the market for a hydraulic thread rolling machine, here are some tips on where to find the best deals:

Manufacturers

Hydraulic thread rolling machines can be found on a variety of manufacturers such as Awnail at different price points. Be sure to compare prices and read reviews to find the best machine for your needs.

Local Retailers

Local retailers may have better prices on hydraulic thread rolling machines and a roll thread machine than online retailers. It’s worth checking with local hardware stores or tool rental shops to see if they have any machines for sale.

Machine Auctions

Hydraulic thread rolling machines and a bolt thread rolling machine are often found at auctions, with prices typically ranging anywhere from US$300 to US$3,000.

Hydraulic thread rolling machine and fully automatic thread rolling machine auctions are hard to predict and prices may vary dramatically depending on the condition of the equipment.

Wherever you ultimately purchase your hydraulic thread rolling machine, be sure to read reviews and compare prices before making a final purchase.

Hydraulic thread rolling machines can be purchased through many different retailers and each retailer will offer the hydraulic thread rolling machine price depending on their overhead and location.

9. How to Take Care of Hydraulic Thread Rolling Machine

Hydraulic thread rolling machines are precision tools that require some special care to ensure they function properly and last a long time.

Here are some tips on how to take care of your hydraulic thread rolling machine:

Use the Correct Lubricant

Always use the correct lubricant for your machine. Hydraulic oil should be used for machines with an oil bath, while light mineral oil or silicone-based lubricants can be used for machines with a water bath.

Keep the Working Area Clean

Be sure to keep the working area clean and free of debris. This will help keep the machine running smoothly.

Fasten the Dies in Place

Make sure the dies are properly aligned and fastened in place. Improper alignment can cause damage to the machine.

Maintain Proper Fluid Levels

Keep an eye on the hydraulic fluid level. Low fluid levels can cause the die to drop out of place or create some other damage.

10. 3 Tips on Choosing the Right Hydraulic Thread Rolling Machine for Your Needs

When selecting a hydraulic thread rolling machine, there are a few factors you will need to consider.

#1 Size of the Machine

The first is the size of the machine. You will want to choose a machine that is the appropriate size for the job at hand.

To choose the appropriate size of machine for your needs, you will need to know how much material you will be using. The larger the job, the bigger the hydraulic thread rolling machine you will need.

#2 Type of Raw Material

The second factor to consider is the type of material you will be using. Some materials are harder to work with than others, so you will want to make sure the machine can handle the type of material you will be using.

Hydraulic thread rolling machines are designed to work with specific materials. They can process steel, aluminum, or other metals, depending on the machine you choose.

#3 Consider the Price

Finally, you will want to consider the price of the machine and make sure it is within your budget. The more expensive a machine, the higher quality it will be. Hydraulic thread rolling machines can range from US$300 to US$50,000.

11. Conclusion

The Hydraulic Thread Rolling Machine is an efficient machine that can help with the production of coils. This machine has a variety of uses, including rolling steel wires and cables into coils.

With its automatic lubrication system, it provides constant oiling of parts that are most susceptible to wear during operation, reducing maintenance costs associated with keeping the equipment maintained. To get your Automation-grade Automatic thread rolling machine, contact us at Awnail now!