Is your search for reliable thread rolling machine suppliers leaving you overwhelmed? Discovering the right supplier is not just about fulfilling orders; it’s about enhancing operational efficiency and product quality.

Utilizing extensive industry experience and knowledge, we understand the complexities of sourcing the ideal machine suppliers, ensuring you benefit from insights that are both practical and relevant.

Selecting the right thread rolling machine suppliers is essential for maintaining a competitive edge in the industry. It’s a decision that influences not only the quality of the products but also the reliability and efficiency of the production line.

In this guide, we will outline a structured pathway in evaluating and selecting suppliers, ensuring they meet your specific requirements for quality and compatibility with your business.

Read on for strategic insights into smart supplier selection.

Step#1 Defining Your Thread Rolling Machine Needs

Identifying your specific machine needs is a crucial first step for ensuring efficient and customized operations. Here are key actions to take in this process:

- Machine Size and Type Selection: Select the appropriate machine size and type that fits the workspace and production line. Measure the available space and match it with the machine’s physical dimensions and type.

- Production Speed Requirement: Determine the production speed required. Calculate the daily or weekly production targets and choose a machine that can meet these output goals. Awnail provides versatile machines capable of handling various production speeds to meet every business’ needs.

- Thread Dimension and Tolerance Specification: List down the thread dimensions and tolerances the products require. This involves detailing the exact measurements and tolerances to ensure the machine can produce threads that meet the product specifications.

- Control and Automation Features Decision: Decide on the necessary control and automation features for the operation. Evaluate the process for areas where automation can improve efficiency and choose a machine with the corresponding features.

- Maintenance and Upkeep Planning: Plan for the long-term maintenance and upkeep of the machine. Assess its capacity for regular maintenance tasks and select a machine whose upkeep requirements align with the resources.

Step#2 Initiating the Search for Suppliers

Building on the understanding of the machine needs, the next step involves actively searching for suppliers to meet those specific requirements. Here’s how to begin effectively:

- Leveraging Industry Networks: Reach out to your business contacts and industry associates to ask for supplier recommendations. Utilize their experience and insights to compile a list of potential suppliers.

- Utilizing Online Directories and Platforms: Search through online directories and platforms for suppliers of thread rolling machines. Filter the search based on location, capacity, and product range to narrow down potential candidates.

- Attending Trade Shows and Expos: Plan to visit trade shows and expos where thread rolling machine suppliers exhibit their products. Use these events to directly engage with suppliers and gain hands-on insight into their offerings.

- Analyzing Competitor Supply Chains: Examine the suppliers your competitors use by reviewing their product literature, case studies, or press releases. This research can uncover experienced suppliers already familiar with industry-specific needs and standards.

Step#3 Conducting Preliminary Research on Potential Suppliers

Following the initiation of the supplier search, next is to conduct preliminary research on potential suppliers to gain insights into their capabilities and compatibility. Here are the aspects to focus on:

- Reviewing Supplier Histories: Conduct research on the history of each supplier through online business directories and their own websites to understand their years in business and past client engagements. Look for any major events or changes in their business that might impact their reliability.

- Analyzing Product Catalogs: Examine each supplier’s product catalog, ideally available on their websites or through direct requests, focusing on the range, specifications, and compatibility of their offerings with your needs. This ensures their product line matches what you’re looking for.

- Customer Reviews and Testimonials: Gather customer feedback by visiting industry forums, review sites, and the supplier’s own testimonial page. This helps in assessing their market reputation and customer satisfaction levels.

- Financial Stability and Reputation: Conduct a financial health check of the suppliers by accessing their publicly available financial records or reports, and seek opinions from industry analysts or forums for insights into their market reputation.

Step#4 Evaluating Supplier Credentials and Experience

After conducting preliminary research, evaluating their credentials and experience thoroughly is crucial for ensuring a reliable and sustainable partnership. Here’s what to consider:

- Compliance with Industry Regulations: Ensure the supplier complies with relevant industry regulations. Check for any necessary licenses or regulatory approvals that are essential for operating in your sector.

- Scrutinizing Technical Certifications: Verify supplier’s technical certifications by directly contacting the organizations that issued the supplier’s technical certifications to confirm their validity. Awnail maintains up-to-date, verifiable certifications, showcasing our commitment to quality and reliability.

- Assessing In-House Expertise: Look into the qualifications and experience of the key personnel, especially those who will be directly involved in the project. For instance, consider the technical expertise of the engineers in handling complex thread rolling projects.

- Evaluating Supplier’s Innovation and Adaptability: Assess the supplier’s adaptability by examining their track record in embracing new technology and industry trends. Review their product evolution, patents, technological advancements and market responses via press releases, catalogs, and reports.

Below is a table that outlines key criteria for assessing a supplier’s capability in innovation and adaptability, along with the strategic importance of each criterion.

| Criteria | Assessment Method | Strategic Importance |

| Product Evolution | Review the supplier’s product lineup changes and enhancements over time. | Future Compatibility: Ensures the supplier’s products will continue to meet your business’s growing and changing needs. |

| Technological Advancements | Examine new technologies the supplier has integrated into their products or manufacturing processes. | Cutting-Edge Solutions: Access to the latest technological innovations can improve your product offerings and operational efficiency. |

| Industry Trends | Assess the supplier’s responsiveness to industry trends, such as sustainability or automation. | Market Relevance: A supplier that stays abreast of trends can help you remain competitive and responsive to market demands. |

| Patents and Intellectual Property | Look into the supplier’s patents and other intellectual property to gauge their focus on innovation. | Unique Offerings: Patents indicate a commitment to developing new solutions, potentially offering you a competitive edge. |

| R&D Investment | Investigate the supplier’s investment in research and development activities. | Continuous Improvement: A strong R&D focus suggests the supplier is committed to innovation and quality improvements. |

| Market Response | Analyze market responses and customer reviews to gauge the reception of the supplier’s innovations. | Proven Effectiveness: Positive market feedback indicates that the supplier’s innovations are valuable and effective. |

| Collaboration with Technological Partners | Explore partnerships the supplier has with tech companies or research institutions. | Extended Expertise: Collaborations can enhance the supplier’s technological capabilities and innovation potential. |

| Adaptability Case Studies | Review case studies or examples where the supplier has quickly adapted to changes or challenges. | Resilience: Demonstrates the supplier’s ability to pivot and adapt in response to unforeseen circumstances, ensuring supply chain stability. |

Step#5 Making Initial Contact with Suppliers

Following the evaluation of supplier credentials, it’s time to initiate contact to establish a foundational conversation and clarify specific needs. Here are crucial actions to take when reaching out:

- Preparing a Comprehensive Inquiry Document: Compose a concise inquiry document outlining your company’s requirements, specifications, and questions. This clear and detailed list will facilitate effective communication and establish a professional tone for the interaction.

- Leveraging Email for Initial Contact: Utilize email as the primary mode of initial contact, providing a concise yet informative introduction of your company and its needs. Attach the prepared inquiry document to ensure organized and clear communication.

- Engaging Through Industry-Specific Online Forums: Participate in specialized online forums where suppliers are active. Ask questions about thread rolling machines to assess suppliers’ knowledge and involvement. Use these interactions as a soft introduction to your company and its needs.

- Conducting an Introductory Phone Call: Organize an introductory phone call to further discuss your needs and establish a verbal communication channel. Prepare a brief agenda, including a summary of your requirements and key questions to make the conversation focused and productive.

Step#6 Assessing Supplier Responses and Proposals

After initiating contact with suppliers, meticulously assess their responses and proposals to ensure alignment with the technical and business requirements. Here are the critical steps to undertake:

- Analyzing Response Time and Detail: Track the time taken by each supplier to respond to your inquiries and note the level of detail in their answers. Quicker responses with comprehensive information suggest a supplier’s efficiency and commitment to customer engagement.

- Reviewing Customization Options: Carefully check each proposal for the ability to customize machines according to your specific needs. Confirm that the supplier can adapt their products to meet unique requirements for thread rolling machines.

- Evaluating Warranty and Support Terms: Examine the warranty periods and support services outlined in each proposal. Look for those who offer extensive warranty coverage and strong after-sales support. Spherical Insights predicts a 7.30% CAGR for warranties from 2021 to 2030.

- Assessing Financial Terms and Payment Options: Review and compare the financial terms and payment options offered by each supplier. Choose a supplier whose payment terms align with the financial planning and budgetary limitations, ensuring a feasible financial partnership.

Step#7 Conducting Site Visits and Meetings

Following the assessment of supplier responses and proposals, site visits and meetings are also crucial for validating the information provided. Here are the vital actions:

- Planning Effective Site Visits: Arrange visits to the shortlisted suppliers’ facilities, ensuring you have a checklist of key aspects to observe. During each visit, focus on verifying their operational capabilities and the truthfulness of their claims.

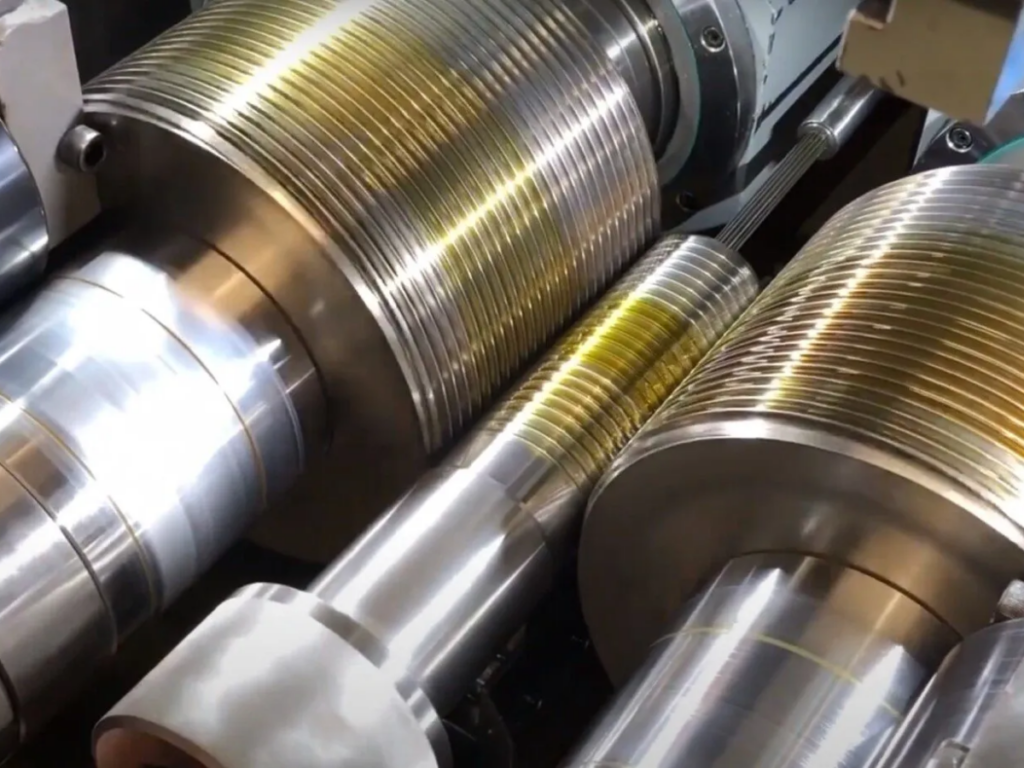

- Evaluating Production Facilities: Carefully inspect the condition and setup of the production facilities. Look for modern equipment, orderly processes, and evidence of quality control measures in place. For example, utilization of advanced automation highlights efficiency and innovation.

- Discussing Long-term Support and Services: Directly discuss and confirm the availability of after-sales support, including maintenance and spare parts. Clarify terms for these services to ensure ongoing support for machinery. Ensuring this now can save time and resources later.

- Meeting Key Personnel: Meet with the supplier’s key personnel, including managers and technical experts to understand their expertise and role in ensuring product quality. Use these meetings to assess the supplier’s technical competence and customer service approach.

- Assessing Cultural Fit: During your visit, interact with various team members to understand the supplier’s work culture and values. Evaluate how their communication style, work ethic, and business practices align with your organization’s culture.

Step#8 Final Evaluation and Decision Making

After conducting site visits and meetings, the last phase is the final evaluation and decision-making to select the most suitable thread rolling machine supplier. Here’s how to conclude the search effectively:

- Reviewing All Collected Data: Go through all gathered information, from supplier credentials to feedback from site visits. Use this collected data to objectively compare and contrast the potential suppliers.

- Seeking External Advice if Necessary: If decisions seem complex, reach out to industry consultants or experienced peers for advice.Their insights can provide a different perspective, aiding in making a well-rounded decision.

- Considering Total Cost of Ownership: Calculate the overall expenses, including the initial purchase, maintenance, and operational costs of the machines. This total cost analysis will help in understanding the long-term financial impact of your choice.

- Prioritizing Supplier Relationships: Identify suppliers who show a strong commitment to customer service and a willingness to engage in a collaborative partnership. Focus on those who are responsive to your needs and demonstrate a clear understanding of your business objectives.

- Making the Final Decision: Assess all the information you have gathered in relation to your business objectives and requirements. Proceed to select the supplier that most effectively meets your criteria, long-term goals, and promises the greatest value for your operation.

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

- 9 Key Stages to Assess Thread Rolling Machine Manufacturers

- 10 Key Factors in Choosing the Best Thread Rolling Machine Manufacturer for Your Needs

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- An In-Depth Guide to Nail Making Machines

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

Finding top-tier thread rolling machine suppliers is crucial in ensuring operational excellence and long-term business success. This guide offers essential strategies and practical tips to simplify your search, ultimately leading to more informed and beneficial supplier partnerships.

Turn to Awnail for specialized support and top-quality thread rolling machines, committed to elevating your business with advanced solutions. Contact us for a partnership focused on your success.