How can you make sure you’re choosing the right nail making machine for your business’s needs? The choice can significantly influence your production efficiency and overall success.

Our guide is backed by extensive industry experience and deep knowledge, providing trustworthy and essential insights for informed decision-making in your purchasing journey.

Selecting an appropriate nail making machine is not just about fulfilling an operational need; it’s about empowering the business to produce high-quality nails with efficiency, reflecting the commitment to excellence in the industry.

In this guide, we will explore the world of nail making machines, covering everything from various models and pricing strategies to crucial features and expert tips for picking the ideal manufacturer.

Read on to discover expert guidance!

1. Understanding Nail Making Machines

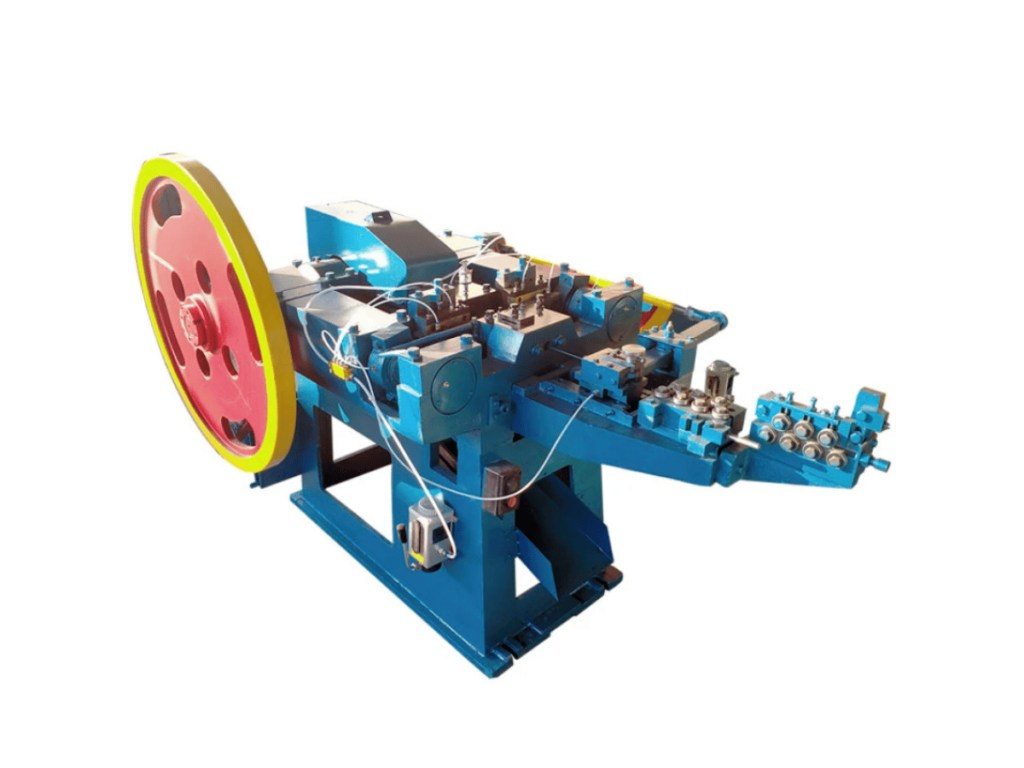

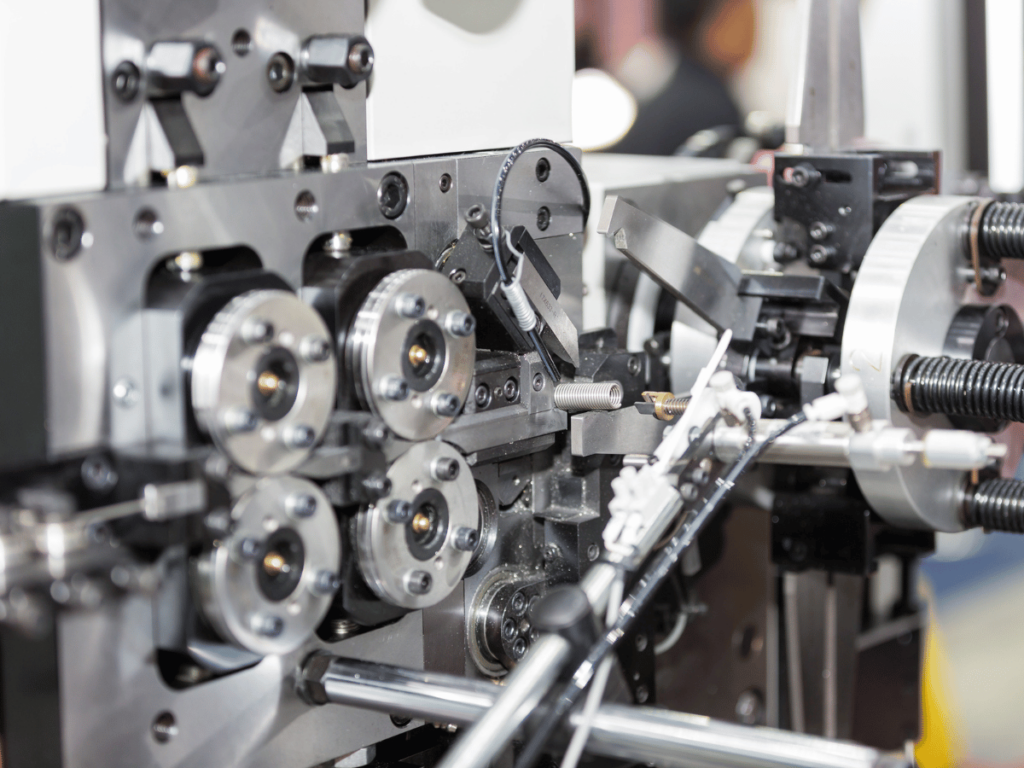

Nail making machines are essential tools in the production of various types of nails, tailored to meet diverse industry requirements. These machines function by transforming raw materials such as wire into nails through a series of precise, automated processes. Their design focuses on efficiency and accuracy, ensuring a consistent output of high-quality nails.

Modern nail making machines integrate cutting-edge technology to optimize production, reduce waste, and enhance safety. They offer customizable settings to produce nails of different sizes and shapes, catering to specific construction and manufacturing needs. Understanding the capabilities and functionalities of these machines is crucial for any business involved in nail production.

2. Types of Nail Making Machines

Bridging the gap highlighted in the understanding of these machines, it’s time to focus on its various types catering to distinct manufacturing requirements. Here are some of the common types:

High-Speed Nail Making Machines

High-speed nail making machines are engineered for optimal efficiency, focusing on rapid nail production. They are particularly suitable for large-scale manufacturing, where high output and consistent quality are essential. These machines are a go-to choice for businesses prioritizing quantity without sacrificing nail integrity.

Wire Nail Making Machines

Wire nail making machines offer versatility and precision, utilizing a continuous wire supply to produce a wide range of nail sizes. These machines are known for their adaptability, catering to diverse nail specifications with consistent accuracy. They are ideal for businesses seeking to produce a broad range of nail types from a single machine.

Coil Nail Making Machines

Coil nail making machines efficiently create nails for nail guns by organizing them into coils. These machines are essential in construction and carpentry, offering quick-loading nail guns and efficient production of large quantities of collated nails for high-demand industries. Awnail offers a range of these machines, catering to the needs of various industries with precision and reliability.

Automatic Nail Making Machines

Automatic nail making machines, showcasing the highest level of technology in nail manufacturing, are set to see significant growth, with a projected 5.9% CAGR from 2023 to 2030, as per LinkedIn. Equipped with advanced control systems and automation, they minimize manual intervention while maximizing output, ideal for businesses looking to modernize their nail production with cutting-edge solutions.

3. Price Range of Nail Making Machines

Nail making machines come in a diverse price range, reflecting their varying features and capabilities. Entry-level machines, suitable for small-scale operations, can start from as low as $1,500. On the other hand, mid-range models, offering better efficiency and features, typically range between $5,000 and $15,000.

For more advanced, high-capacity nail making machines, prices can escalate to $20,000 and beyond, depending on their sophistication and technological advancements. These machines are designed towards large-scale production and offer superior speed, automation, and customization capabilities. Investing in these machines is often worth it due to their improved efficiency and long-term cost savings.

4. Key Features to Consider When Choosing a Machine

After considering the price range of nail making machines, it’s crucial to focus on the key features that define their functionality and efficiency. Here are the essential features to evaluate:

Noise and Vibration Control

Noise and vibration levels are critical factors, especially in environments where multiple machines operate simultaneously. Machines designed with noise reduction and vibration control technologies ensure a more comfortable working environment and reduce wear and tear. Choose a machine that emphasizes these aspects to enhance workplace safety and prolong the machine’s lifespan.

Automation Level

The automation level of a nail making machine determines the extent to which it can operate with minimal human intervention. Higher automation means the machine can perform tasks like feeding materials, cutting, and sorting with minimal manual input. This not only increases efficiency and consistency but also reduces labor costs and error rates.

Real-time Monitoring Systems

Real-time monitoring systems are integrated into the machine to provide continuous supervision of the production process. These systems track performance metrics, alert operators to any malfunctions, and ensure consistent quality. They are crucial for maintaining high standards of production and for quickly addressing any issues that arise.

Real-time monitoring systems play a pivotal role in modern manufacturing processes, particularly in the nail making machine industry, where they ensure high production standards and rapid response to operational issues. The table below outlines the key features of these systems, their benefits, and considerations for implementation.

| Feature | Benefit | Consideration |

| Performance Metrics Tracking | Enables precise monitoring of production speed, quality, and efficiency metrics. | Ensure the system can be customized to track the most relevant metrics for your specific production goals. |

| Automated Alerts | Sends instant notifications to operators about malfunctions or deviations from standard parameters. | Alerts should be easily distinguishable and actionable, ensuring quick response times to prevent downtime or quality issues. |

| Quality Assurance | Continuously assesses product quality against predefined standards to ensure consistency. | Quality parameters should be adjustable to align with different product specifications or regulatory requirements. |

| Predictive Maintenance | Utilizes data analytics to predict equipment failures before they occur, allowing for preemptive maintenance. | Integration with maintenance schedules and inventory management systems for replacement parts can optimize machine uptime. |

| Remote Monitoring | Allows for the supervision of production processes from remote locations, offering flexibility in management. | Robust security measures are essential to protect against unauthorized access and data breaches. |

| Data Analysis and Reporting | Collects and analyzes production data to identify trends, efficiencies, and areas for improvement. | Data should be accessible in user-friendly formats, enabling easy interpretation and strategic decision-making. |

| Energy Consumption Monitoring | Tracks energy usage of machines, identifying opportunities for reducing operational costs. | Consideration of energy efficiency measures can lead to significant cost savings and environmental benefits. |

| Integration with Other Systems | Seamlessly integrates with other manufacturing and business management systems for a holistic view of operations. | Ensure compatibility and interoperability with existing software platforms to leverage the full potential of data insights. |

5. Where to Purchase Nail Making Machines

Considering the key features of nail making machines, it’s crucial to identify where to purchase them for optimal quality, reliability, and value. Here are the most reliable sources to consider:

Manufacturers’ Websites

Interested parties visit manufacturers’ websites by simply searching online using keywords related to nail making machine manufacturers. On this website, buyers can access detailed information about the machines they offer, review specifications, and easily request price quotes to make an informed purchase decision. This also ensures that buyers obtain original equipment along with extensive after-sales services.

Through Authorized Distributors

Machines are acquired through authorized distributors listed on Alibaba and Made-in-China, where authenticity and warranty coverage are assured. These platforms facilitate easier access to a broad range of machines, along with the convenience of comparing different models and prices. Authorized distributors provide localized support and speed up shipping options.

Online Industrial Marketplaces

Buyers navigate ThomasNet and IndiaMART for a comprehensive selection of nail making machines from various global suppliers. These marketplaces offer the advantage of comparing machine specifications, prices, and supplier reputations in a centralized location. Transactions are safeguarded by buyer protection policies, ensuring a secure purchasing process.

Trade Shows and Industrial Exhibitions

Events such as the International Fastener Expo or Hannover Messe present an opportunity to explore various nail making machines, witness live demonstrations, and gain firsthand experience. These events are ideal for networking with industry professionals and learning about the latest manufacturing trends. They also provide a platform for direct interaction with manufacturers and experts.

6. 4 Tips for Selecting a Reputable Manufacturer

After exploring where to purchase these machines, choosing the right manufacturer is critical, ensuring they provide quality machines and align with long-term goals. Here are vital aspects to consider:

#1 Industry Expertise and Specialization

Evaluate the manufacturer’s expertise and specialization in the nail making industry. Manufacturers who specialize in nail making machines are likely to have deeper insights and more improved technology specific to the business’ needs. Their expertise often translates into better-designed machines and can offer businesses a competitive edge in the market.

#2 Global Presence and Market Footprint

A manufacturer’s global presence and market reach are key indicators of reliability and reach. Strong global presence means more experience in meeting diverse customer needs and international standards, leading to strong supply chains and reliable global support and innovation. Awnail, with its worldwide presence, showcases these traits, guaranteeing strong and innovative solutions for its clients.

#3 Quality Certifications

Quality certifications are a testament to a manufacturer’s adherence to international standards. For example, a manufacturer holding an ISO 9001 certification showcases their commitment to maintaining high-quality products and processes. These certifications are a reliable standard for comparing different manufacturers, serving as a standard for quality and reliability in the industry.

#4 Customer Service and Communication

Effective customer service and clear communication showcases a reputable manufacturer. Look for a company that is responsive, communicates clearly about product specifications and services, and is willing to engage with questions and concerns. Good customer service can make a significant difference in resolving issues quickly and effectively, ensuring smooth operation.

7. Factors to Consider When Buying Nail Making Machine

Once manufacturer’s reputation is verified, when selecting a nail making machine it’s crucial to consider several factors that will impact production. Here are vital elements to evaluate:

Compatibility with Existing Systems

Ensure the new machine is compatible with the existing production line for smooth integration. For instance, if the current system mostly produces roofing nails, the new machine should work well with this type of production. Evaluate if it easily fits with the workflow, automation, and quality control measures in place. This compatibility simplifies the production process, reducing the need for costly modifications.

Scalability and Future-Proofing

When investing in a nail making machine, consider its scalability and potential for future upgrades. A machine that can grow with the business and adapt to future technological advancements is a more sustainable investment. Look for machines that offer modular upgrades or have a track record of easy integration with new technologies.

Production Speed vs Quality

Balancing production speed with quality is essential in nail manufacturing. A machine that operates at high speed is advantageous for meeting large orders quickly, but it should not compromise the integrity and uniformity of the nails produced. It’s important to choose a machine that maintains consistent quality even at higher speeds, ensuring the end product meets industry standards.

User Interface and Control Systems

The user interface and control systems of a nail making machine play a crucial role in its ease of operation. Look for machines with clear, straightforward interfaces that make setting adjustments and daily operations simple and efficient. A user-friendly control system reduces training time and helps prevent operational errors, enhancing overall productivity.

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

- Top 5 Considerations When Purchasing Nail Making Machine

- Nail Machine Purchasing Pitfalls: 10 Mistakes to Avoid

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

Diving into the complexities of nail making machines reveals key factors for efficient, high-quality nail production. This guide has shed light on these aspects, equipping you with the knowledge to make strategic choices in right machine selection and procurement.

Explore superior nail making machine solutions with Awnail. Our expertise ensures you get the best equipment and support. Contact us for tailored assistance in enhancing your production process.