Are you overwhelmed by the options when it comes to choosing a wire drawing machine for your business? Optimizing your wire production process starts with the right equipment.

Utilizing our extensive industry experience, we offer insights grounded in years of expertise in wire drawing machines. Trust our guidance to select a machine that meets your exact needs.

Here is a sneak peek at 2 of the critical tips to remember, ensuring alignment of wire drawing machines to your business requirements and goals:

- Assess Your Wire Specifications

- Consider Production Volume

In this guide, you’ll be equipped with essential tips that shed light on the complexities of choosing a machine that’s not just good, but the best match for your wire drawing ambitions.

Continue reading to unlock these insights!

1. Assess Your Wire Specifications

Understanding wire requirements is crucial for selecting the appropriate wire drawing machine, ensuring it aligns with production needs. Here are the factors that need close examination:

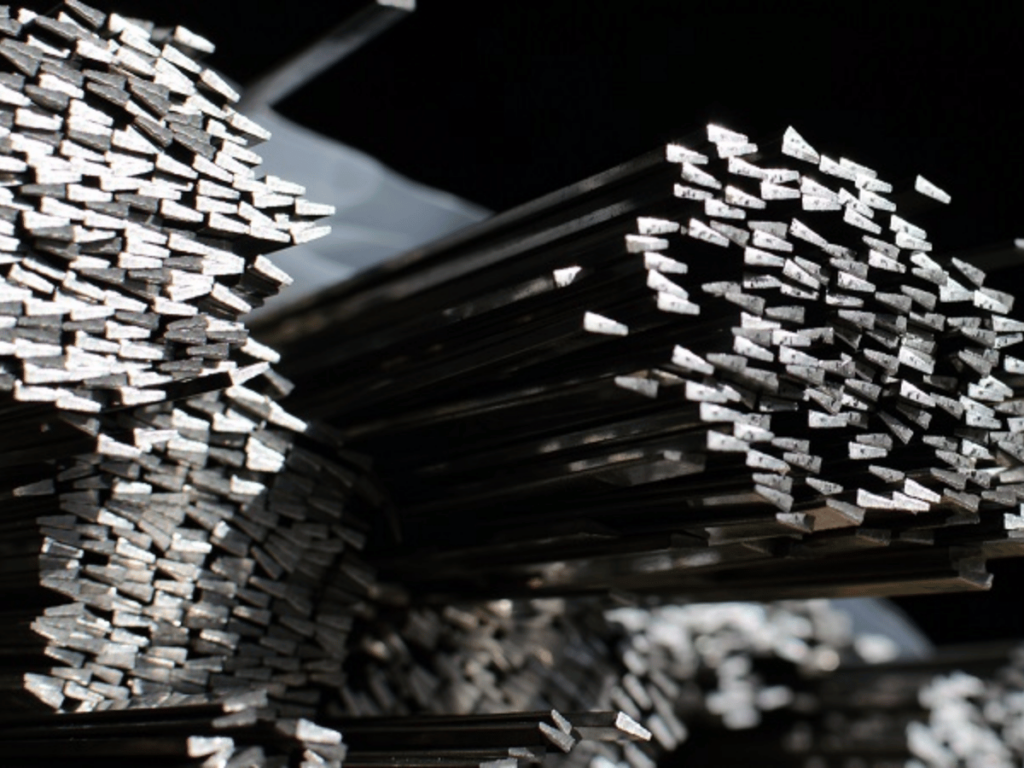

Wire Material

The material of the wire dictates the type of drawing machine required due to its impact on the drawing process. Different materials, such as copper, aluminum, or steel, have varying degrees of hardness and flexibility, which influence the machine’s design and capability. Selecting a machine compatible with the wire material ensures efficient production and minimizes wear on the machine.

Wire Diameter

The range of wire diameters you plan to produce directly impacts the type of drawing machine needed. A machine that can handle a wide range of diameters provides greater flexibility for future projects. Consider machines that offer easy adjustments to different diameters to simplify the production process and minimize downtime. It’s a win-win situation for your business.

Wire Shape

Wire drawing machines are tailored to produce specific shapes, such as round, square, or hexagonal wires. The shape of the wire influences the die design and the complexity of the drawing process. Look for a machine that not only produces the current shapes needed but also has the capability to accommodate any potential future requirements for different wire shapes.

2. Consider Production Volume

By balancing the production needs with machine capacity optimization of resources and reduction of operational issues are more possible. Here are the production volumes to be considered:

Small-scale Production

Small-scale production requires a machine that offers flexibility rather than high-speed mass production. These machines are perfect for businesses that need to produce a variety of wire types in smaller quantities. They have lower initial costs and can be easier to adjust for different wire specifications, making them ideal for startups with diverse and low-volume needs.

High-volume Production

For businesses aiming for high-volume production, select a machine designed for large-scale operations. These machines are engineered to handle continuous and high-speed production with minimal downtime. They provide limited product variety but excel in efficiently producing large quantities of wire, crucial for meeting demands of large orders and staying competitive in the market.

Batch Processing

Companies relying on batch processing should pick machines capable of quickly transitioning between wire types and specifications, ensuring flexibility without compromising efficiency. These machines minimize setup time between batches, ideal for accommodating diverse demands by quickly adapting to varying wire types. Awnail excels in this field, offering highly effective machines to meet various demands.

3. Evaluate Machine Quality

Selecting durable machinery is critical for maintaining long-term efficiency and minimizing downtime and maintenance, ensuring a reliable production process. Here are aspects to be evaluated meticulously:

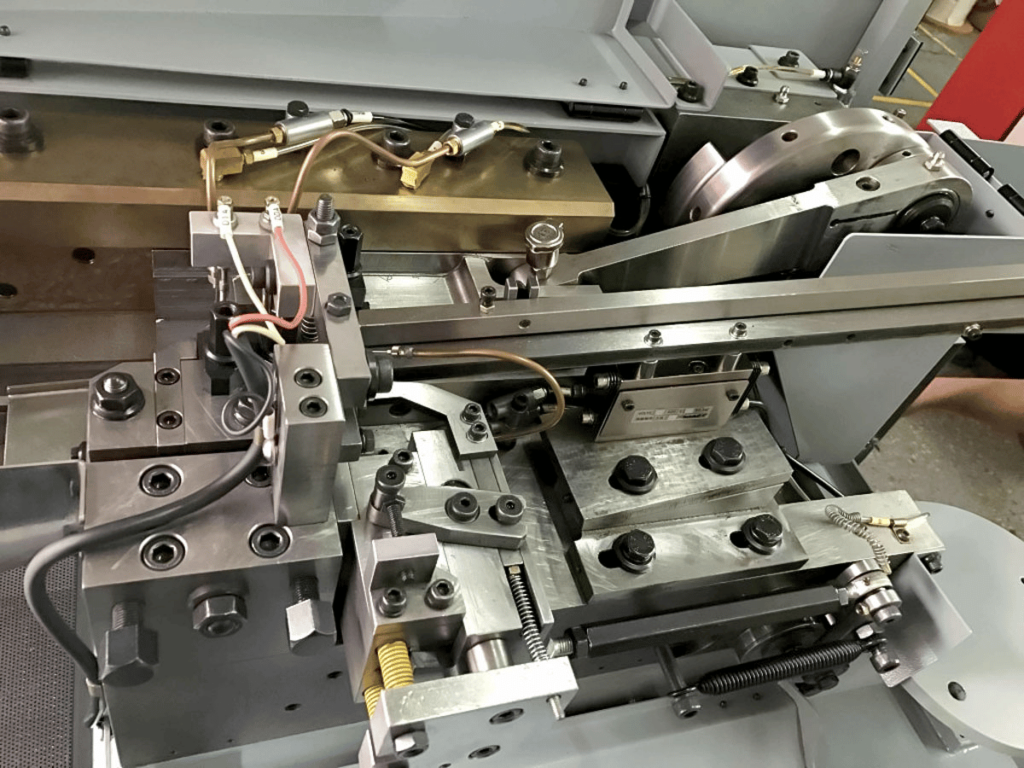

Component Quality and Machine Assembly

The quality of components used in a wire drawing machine and its assembly precision are vital for ensuring operational reliability. Check premium components, such as bearings, motors, and dies to ensure longer machine life and less frequent need for replacements. Ensure that all parts are properly assembled, reducing the risk of mechanical failures and ensuring smoother operations.

Control System Sophistication

Sophisticated control systems in machines directly influence usability and output consistency. Advanced systems provide precise adjustments, real-time feedback, and smooth integration with other manufacturing systems, optimizing production processes. Examine the system’s user interface, customization options, and automation capabilities to reduce errors and improve consistency.

Structural Integrity and Design Efficiency

The structural integrity and design efficiency of the machine contribute to its overall quality. Analyze its design efficiency, focusing on material flow, maintenance accessibility, and part replacement ease to minimize downtime. Ensure the machine’s compactness suits the operational space while enhancing overall production efficiency and maintenance workflow.

4. Check for Customization Options

Customization options are essential for adapting to varied production requirements, enhancing machine utility and enabling it to evolve with changing business needs. Here are vital options to examine:

Modular Design Components

Explore the availability of interchangeable modules that allow for the machine to adapt to various wire production types. With this versatility, you can ensure satisfaction and repeat business. These include modules for different wire sizes, materials, or specialized drawing processes. This enables adapting production to market changes or expanding product variety without extra costs.

Material Handling and Feeding Systems

Focus on the machine’s material handling and feeding mechanisms to ensure they can be adjusted for different wire types and sizes. Check if the system can automatically adapt to material variations, which would reduce manual setup time and improve operational continuity. Customizable systems that efficiently manage material variations are crucial for productivity in diverse production settings.

Die Configuration Flexibility

Evaluate the machine’s die setup for its adaptability to different wire sizes and shapes. Consider how efficiently and rapidly die configurations can be changed, along with the machine’s capacity to accommodate various setups. This ensures that production remains responsive to customer needs. Awnail’s wire drawing machines showcase versatility, effortlessly meeting evolving business requirements.

5. Review Speed and Efficiency

Selecting a wire drawing machine involves balancing production speed with wire quality to avoid rejections and maintain credibility. Here are key factors to review in this domain:

Throughput Capacity

Evaluate the machine’s ability to process a significant volume of wire within a specific period. It’s essential to examine the machine’s maximum operational speed and how this translates into actual wire output, considering the typical production runs. Comparing this capacity against demand forecasts ensures the machine meets production needs efficiently, avoiding downtime and excessive costs.

Efficiency in Material Usage

Examine how accurately the machine draws nails and how well it reduces waste. Explore the technology used in controlling material feeding and drawing speeds, keeping in mind your unique business objectives and production demands. As these impact material usage during start-up, shutdown, and transitions. Assess also its features for recycling waste materials to improve efficiency and reduce raw material costs.

Dynamic Speed Adjustments

Focus on the machine’s ability to change drawing speeds according to different wire types, sizes, and quality requirements. For example, evaluate control systems like programmable logic controllers or advanced digital interfaces for accurate adjustment of production parameters. Ensure that the machine can transition between products or specifications while maintaining efficiency and output quality.

6. Evaluate Machine Features

Selecting a machine with the right features is crucial for optimizing production, as these features should align with operational needs, enhancing efficiency and quality. Here are some key features to consider:

Advanced Sensor Technology

Evaluate the range and precision of sensor technology integrated into the machine. The sensors should be capable of accurately monitoring critical parameters such as wire tension, temperature, and speed, providing real-time data for optimal control. Assess whether sensor technology can automatically adjust process parameters to maintain consistent wire quality, reducing manual oversight and error.

Remote Monitoring and Control

Investigate the capabilities and security features of the machine’s remote monitoring and control systems. Peace of mind comes from secure and accessible operations. Ensure that the system offers comprehensive access to machine settings, performance data, and alarms through a user-friendly interface. Evaluate its effectiveness to minimize downtime and support efficient maintenance practices.

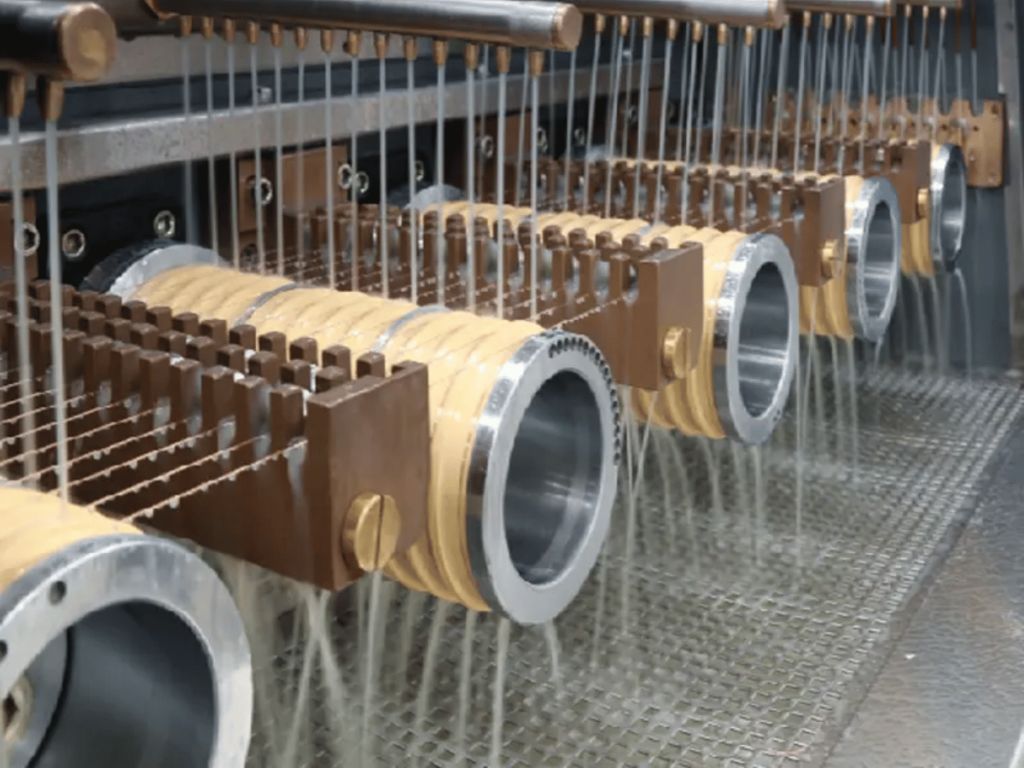

Multi-wire Drawing Capabilities

Assess the multi-wire drawing capacity of the machine, including simultaneous wire processing and supported diameter range. Evaluate the system’s ability to maintain consistent quality across all wires, despite increased production. Consider the machine’s flexibility in adjusting individual parameters for each wire, ensuring the capability to meet diverse production requirements within a single operation.

7. Assess Ease of Operation and Maintenance

Choose user-friendly machines for increased productivity and longevity, prioritizing accessibility and clear maintenance instructions for optimal performance. Here are the key factors to assess:

Intuitive Control Panel Design

An intuitive control panel is key for straightforward machine operation. It should feature easily understandable controls and a clear display, allowing operators to quickly make adjustments and monitor the machine’s status without confusion. Look for a user-friendly interface that minimizes errors and simplifies the training process for new users.

Onboard Maintenance Instructions

Ensure machines have readily accessible maintenance instructions for quick access to upkeep information. Assess its ability to offer clear and concise guidance on routine maintenance tasks directly on the machine, either through digital displays or QR codes linked to instructional videos. It’s a valuable tool for ensuring maintenance is performed accurately and efficiently, helping to avoid unnecessary downtime.

Dust and Debris Management Systems

Effective dust and debris management systems are vital for maintaining a clean operating environment and protecting the machine’s internal components. Look for integrated systems that automatically collect and remove waste materials, thereby reducing the need for manual cleaning and prolonging the machine’s lifespan. This not only maintains optimal performance but also contributes to a safer workplace.

The table below highlights key features of effective dust and debris management systems.

| System Type | Key Feature | Benefit |

| Integrated Vacuum Systems | Automatic collection and removal of dust and debris | Minimizes manual cleaning, enhancing efficiency. |

| Cyclone Dust Collectors | High-velocity air flow | Efficiently separates dust from air, reducing particle build-up. |

| Baghouse Filters | Large fabric bags | Captures fine particles, improving air quality. |

| Wet Scrubbers | Liquid-based dust removal | Effectively traps dust, suitable for combustible particles. |

| Electrostatic Precipitators | Electrically charged filters | Removes fine particulates, ensuring clean exhaust streams. |

8. Analyze Energy Consumption

Optimize operational cost-effectiveness by considering the energy consumption of machines, which reduces utility bills and aligns with environmental responsibility. Here are energy-saving aspects to check:

Motor Efficiency

Investigate the motor’s efficiency as it’s a primary consumer of energy in wire drawing machines. Efficient motors cut costs and reduce carbon footprint by converting more electrical energy into mechanical work. This positions the business as a leader in sustainable practices. Seek machines with high energy-efficient motors to reduce power consumption for sustainable production practices.

Standby Mode Energy Consumption

Consider the energy consumption of the machine in standby mode. Machines that consume a significant amount of power even when not actively drawing wire can lead to unnecessarily high energy costs. Look for machines designed with energy-efficient standby modes, which minimize power usage when the machine is not in active operation but still turned on, ensuring that energy is not wasted during downtime.

Variable Speed Drives (VSDs)

VSDs adjust the motor speed to match the load requirement, reducing energy consumption. By ensuring the machine operates only at the needed speed, VSDs cut down on wasted energy, offering flexibility in production without sacrificing efficiency. Examine if the machine incorporates VSD technology to save energy, particularly in operations with varying production speeds and different material types.

9. Prioritize Safety Features

Selecting a wire drawing machine requires prioritizing safety through the incorporation of safety features to mitigate operational risks and reduce liability. Here are vital safety elements to take note of:

Emergency Stop Buttons

Emergency stop buttons are vital safety components for wire drawing machines, reflecting a predicted market growth of 4.9% as per Verified Market Reports. Prioritize accessible and clearly marked emergency stops on the machines to enable instant shutdown and reduce operational risks. Training on the usage and location is also vital for quick response, accident prevention, and a safer work environment.

Guarding and Enclosures

Ensure the installment of protective barriers around moving parts and areas on the machine that pose a risk of injury. These barriers should be made of durable materials to withstand the operational demands while preventing unauthorized access to hazardous areas. By enclosing dangerous parts, the risk of workplace injuries is reduced, making the production environment safer for everyone.

Signaling and Alarms

Focus on the implementation of a comprehensive alert system within the machine. For example, this system should include both visual, like flashing lights, and auditory warnings, like alarms, that activate in response to operational irregularities or safety violations. Ensure placement and sensitivity are heightened to ensure quick issue detection and response, upholding safety standards effectively.

10. Consider Space Constraints

Choose a wire drawing machine that fits the production area to ensure smooth integration and avoid costly modifications or workflow disruptions. Here are spatial considerations needed:

Machine Footprint

Ensure that the machine’s dimensions fit within the allocated space, leaving enough room for operators to maneuver safely and efficiently around it. It’s also crucial to account for additional space that may be needed for other equipment or materials, ensuring the machine’s footprint does not compromise the functionality of the workspace.

Layout Flexibility

Flexibility in the facility’s layout is key to adapting to future changes or growth. Think about how the size and position of the machine will affect the ability to rearrange the workspace or add new equipment. Opt for a machine that requires minimal structural changes for installation or future adjustments to save time and resources, making it easier to evolve the production line as business needs change.

Integration with Existing Equipment

Integrating a new wire drawing machine into the production line demands meticulous planning. Consider how the new machine will integrate with existing processes and equipment to avoid disruptions to current operations. Assess compatibility with material handling systems, production workflows, and any necessary modifications to accommodate the new equipment for efficient operation.

11. Budget Considerations

Carefully weigh budget constraints against efficiency and durability when selecting a wire drawing machine to make informed investment choices. Here are the budgetary factors to take note of:

Initial Purchase Price

Evaluate the initial purchase price by considering the full cost of the machine, including any additional fees for shipping, installation, and initial setup. Saving every dollar upfront boosts profits. It’s wise to compare models and prices from various suppliers to ensure a competitive deal. Negotiate payment terms that align with your financial planning to mitigate upfront financial pressure.

Operating Costs

Operating costs encompass energy usage, routine maintenance, and the need for replacement parts or repairs over the machine’s life. To manage these costs effectively, assess the energy efficiency of the machine, understand the maintenance schedule, and consider the availability and cost of spare parts. Selecting a machine with lower operating costs can significantly reduce the total cost of ownership.

Return on Investment (ROI)

Calculating the return on investment involves analyzing the machine’s potential to increase productivity, reduce costs, or improve product quality, thereby generating more revenue. Consider the machine’s efficiency, speed, and the quality of output when estimating its impact on the operations. A favorable ROI indicates that the machine will contribute positively to the business’s profitability.

Dive Deeper Into Our Resources

Looking for more diverse product options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

- The Ultimate List of Top 8 Nail Making Machine Manufacturers

- An In-Depth Guide to Nail Making Machines

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

As you navigate the complexities of selecting a wire drawing machine, remember the importance of aligning your choice with the production needs and goals. This guide aims to aid your decision-making process, providing you with a comprehensive understanding of the factors involved.

If you’re ready to optimize your operation by utilizing a wire drawing machine, consider Awnail. Explore our precise and efficient solutions. Contact us and let’s elevate your production to new heights.